StrizzyChris

New member

Hey Everyone! Finally got around to making my build thread for the 2013 Dune JKU Rubicon, named Scorpion, that I ordered and received just over a month ago.

This will be a SLOW build, but I will lay out my plan in phases below, that I hope and plan to get me on 40's and 1-tons by the end(within 2 years). I attempted to do this build last year, and shortly after I began to purchase parts I determined I wanted to perform the build on a 2013 JKUR. The determining factor was the new(2012+) 3.6L, rather than my 2007 JKU Sahara with the slug of a 3.8L. And while doing so, I determined a Rubicon would be a better choice for the sway bar, transfer case, lockers, 4.10 stock option gears, etc. This, combined with traveling for work put a temporary hold on my build, but I am now back on track.

Again, this will be a somewhat slow build due to funds, and access to a garage and tools, but the plan remains the same. So bare with me and give me ANY advice you may be able to give in the product and parts I am looking to purchase! Items in red are already purchased items.

Phase-1

•Drag link flip - Rancho front raise TB bracket w/Crown flipped drag link

•Adjustible Track Bar - JKS Gen-II Bar

•Front Drive Shaft - Adams 1310

•Adjustable Front Lower Control Arms - Rock Krawler High Clearance Arms

•Skid system - EVO MFG Full ProTek Skid System

•Flat fender flares - Stock Fender Cut

•4 door Sliders - LOD Signiture Series Sliders

•Bolt on Coilover system - EVO MFG Front and Rear

•Winch Mount Stubby Bumper - EVO MFG 1/4 pounder with Stinger

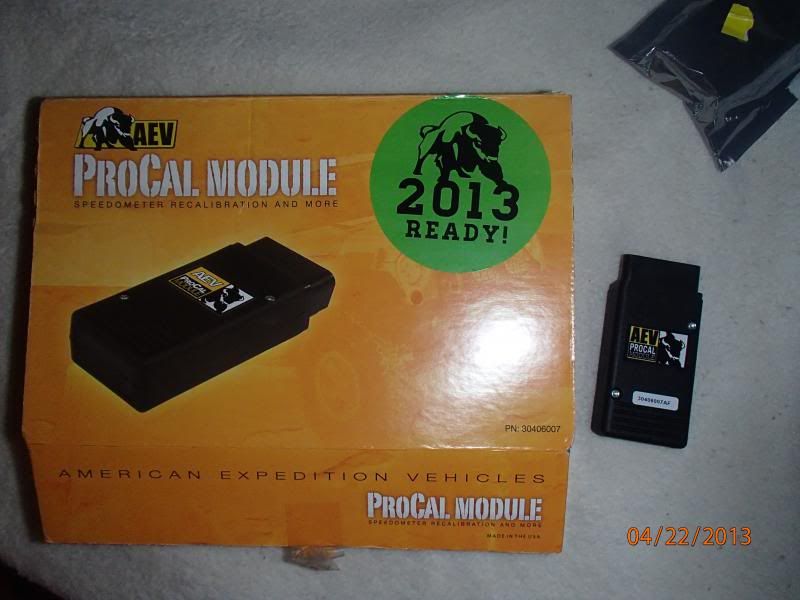

•Speedometer recalibration/Tuner - AEV Procal

•Recovery Gear - Always adding to this

•CB Radio, antenna, and wiring - Cobra 29LX LCD CB

•35” MT tires - Nitto Mud Grappler 35x12.50r17

•Rear Tire carrier - Genright Tire Carrier

•Wheel Spacers - 1.5" Spidertrax

•Inner C-gussets - EVO MFG C2 Gussets

Phase-2

•Bolt-on Long Arm bracketry and control arms

•Electrical wiring system with dash or a-pillar rocker switches

•Hydraulic Assist Steering

•Onboard Air System

•LED Off Road Lighting - Outlaw LED A-Pillar lights with PSC Brackets

•9.5-12K Winch - Warn 9.5ti

•Cat Back Exhaust - DynoMax Evolution Competition Series Exhaust

•Air Bump-stops - King Front Airbumps

•37" MT Tires - Nitto 37x12.50r17 Trail Grapplers

Phase-3

•1 ton axles with 5.13's, 8 on 6.5 lug, ARB, full float rear

•Beadlock 17” 8on6.5 wheels - ATX Slabs

•40” x 17” tires

•Sport cage

•4 point Racing Seats

This will be a SLOW build, but I will lay out my plan in phases below, that I hope and plan to get me on 40's and 1-tons by the end(within 2 years). I attempted to do this build last year, and shortly after I began to purchase parts I determined I wanted to perform the build on a 2013 JKUR. The determining factor was the new(2012+) 3.6L, rather than my 2007 JKU Sahara with the slug of a 3.8L. And while doing so, I determined a Rubicon would be a better choice for the sway bar, transfer case, lockers, 4.10 stock option gears, etc. This, combined with traveling for work put a temporary hold on my build, but I am now back on track.

Again, this will be a somewhat slow build due to funds, and access to a garage and tools, but the plan remains the same. So bare with me and give me ANY advice you may be able to give in the product and parts I am looking to purchase! Items in red are already purchased items.

Phase-1

•Drag link flip - Rancho front raise TB bracket w/Crown flipped drag link

•Adjustible Track Bar - JKS Gen-II Bar

•Front Drive Shaft - Adams 1310

•Adjustable Front Lower Control Arms - Rock Krawler High Clearance Arms

•Skid system - EVO MFG Full ProTek Skid System

•Flat fender flares - Stock Fender Cut

•4 door Sliders - LOD Signiture Series Sliders

•Bolt on Coilover system - EVO MFG Front and Rear

•Winch Mount Stubby Bumper - EVO MFG 1/4 pounder with Stinger

•Speedometer recalibration/Tuner - AEV Procal

•Recovery Gear - Always adding to this

•CB Radio, antenna, and wiring - Cobra 29LX LCD CB

•35” MT tires - Nitto Mud Grappler 35x12.50r17

•Rear Tire carrier - Genright Tire Carrier

•Wheel Spacers - 1.5" Spidertrax

•Inner C-gussets - EVO MFG C2 Gussets

Phase-2

•Bolt-on Long Arm bracketry and control arms

•Electrical wiring system with dash or a-pillar rocker switches

•Hydraulic Assist Steering

•Onboard Air System

•LED Off Road Lighting - Outlaw LED A-Pillar lights with PSC Brackets

•9.5-12K Winch - Warn 9.5ti

•Cat Back Exhaust - DynoMax Evolution Competition Series Exhaust

•Air Bump-stops - King Front Airbumps

•37" MT Tires - Nitto 37x12.50r17 Trail Grapplers

Phase-3

•1 ton axles with 5.13's, 8 on 6.5 lug, ARB, full float rear

•Beadlock 17” 8on6.5 wheels - ATX Slabs

•40” x 17” tires

•Sport cage

•4 point Racing Seats

Last edited: