Ok I'm gonna give my best explanation. The standard front axle on a JK has 6* of caster when your pinion angle is neutral (0*). The stock arms set the pinion angle at +1.8* giving you 4.2* of caster. The Prorock 44 Unlimited has added built in caster. If I remember correctly is has 10* of caster when you pinion angle is neutral (0*). This allows you to add more positive pinion angle without sacrificing caster. This to provide better drive line angles and prevent driveline vibrations. I know this is all clear as mud but I hope this helps. I'm sure someone with more technical knowledge will chime in and add on or correct any misinformation I provided. Hopefully Dynatrac is listening in and can provide you with exact info.

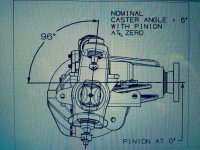

Spot on! Here is right form their web page...."When examining caster angle there are a

couple key points to consider. The first is the

relationship between the end forging king pin axis

and the pinion centerline when viewed directly

from the side of the axle, perpendicular to the wheel

mounting plane. The king pin axis is the centerline

formed by the two ball joints. Its just like a door

hinge set at an angle. The pinion gear accepts

power from the driveshaft and it has a centerline

where it is supported by bearings inside the

housing. The standard JK ProRock 44 axle has 6

degrees between the king pin axis and the pinion

centerline. This matches the stock JK Rubicon D44

axle. Caster is measured relative to the vertical axis

which would be normal to the ground level. When

the pinion angle is zero, caster is equal to the angle

between the kingpin axis and the pinion centerline.

Caster is generally configured between 4 and 8 degrees relative to the vertical axis, depending on

vehicle configuration. As the pinion points up the caster is reduced.

Dynatrac is currently manufacturing the ProRock 44 Unlimited edition axle which includes

more caster. These axles have 10 degrees of separation between the pinion and caster axis. They are

configured for a nominal 7 degrees caster and 3 degrees pinion angle. The axle can be adjusted usingconfigured for a nominal 7 degrees caster and 3 degrees pinion angle. The axle can be adjusted using

the control arms between 6-8 degrees caster and 2-4 degrees at the pinion. Please see our supplemental

document “JK ProRock 44: Choosing the Right Housing for My Jeep” available at the Dynatrac

website for more information about the JK ProRock 44 Unlimited. This can be helpful if you are

running a big lift and need the additional angle. The pinion will point up towards the transfer case front

output yoke without reducing caster to unsafe levels. When the pinion is rotated the upper and lower

control arm mounts must follow the pumpkin while the spring perches need to stay level with the

ground. The control arm mounts must roll up with the pinion because the driver side upper control arm

mount is cast into the pumpkin. The track bar bracket, spring perches, shock mounts, and sway bar

mounts will remain in the stock location while the pinion and control arm mounts rotate to the desired

angle."

Actually makes scents!:brows: