IceKnight

New member

I'm not 100% sure where to begin with my build. Seeing as how I build it once and now have completely torn it down and rebuilt it.

I guess I'll do a short sum up of my Jeeps life and detail the actual build over the past two years or so to get everyone up to speed.

My Jeep started life as a 98 Wrangler Sport with a no name 4 inch lift and 33'' Futura Dakota RVT

Over time I did the normal stuff we all do, front and rear bumpers, rocker guards, suspension, exhaust, tires etc... and it looked like this.

It was around this time that my weekly routine was to get to work early to weld my control arms back on my frame or axle...which ever one decided to rip out that day, gotta love New England and our wonderful rust. After doing this a few to many times my awesome wife gave me the green light to, as she put it "do what you do", and so the work began.

My build so far is looking like this...

Frame

2000

Completely stripped

Coated inside and out with Rust Bullet

New motor mounts

New front track bar mount

New steering linkage mount

Newly fabed rear control arm mounts

Reinforced rust prone areas of frame

New transfer case nutserts

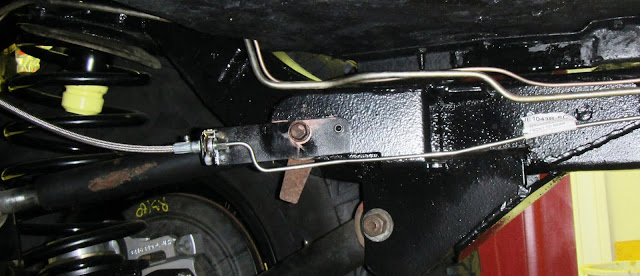

New Classic Tube SS brake lines

Motor

4.6L I-6

4.2 Crank

Brown Dog MML

Icon IC944 .30 pistons

Comp Cams 68-232-4

Mopar performance valve springs / Retainers - 5249464 / 4452032

Mopar performance head gasket - 4529242

Arp head studs

Melling oil pump

62mm TB

Fuel Pump, lines, Ford 24lb Injectors

FAL Fan

Aluminum Radiator

Header

Banks Exhaust

Hi Flow cat

New Gaskets

New Bearings

Custom mounted Amsoil cone filter w/pre-filter

Transmission/Transfer Case

Advanced Adapters SYE

Advanced Adapters Braided Stainless Clutch Line

Novak Transfer Case Shifter

Tom Woods Rear Drive Shaft

Suspension

OME 2.5 HD springs

OME L series shocks

JKS Control arms upper and Lower

JKS Quicker Discos

TNT Front track bar (with replacement frame bracket)

Rokmen .5 body lift

Rokmen bump stops extensions

Rokmen rear spring relocator kit

New bumper jounces

Axles

Front

2000 HP Dana 30

4.10

Solid differential cover

Lube locker

New upper control arm bushings

Gusseted lower control arm mounts and upper control arm mount

New Rotors and Pads

SS Brake Lines

- locker, RCV's, sleeves, Artec truss (ordered), C Gussets (ordered), Currie steering, Vanco BBK

Rear

1999 Ford 8.8

Ford Racing LSD Clutch Packs

4.10

Solid differential cover

Lube locker

New Rotors and Pads

Currie 8.8 brake line kit

Artec Truss

Yukon 8.8 Axles

- Locker

Armor

Rokmen HiLine Tube Fender

Rokmen Stryker Steel Corners

Rokmen Transfer Case Skid

Rokmen Gas Tank Skid

Rokmen Rocker Guards

Rokmen Power Steering Skid

Poison Spyder BFH II Rear Bumper

Mopar Front Rock Bumper

Recovery

Warn M8000-s

Front & Rear Shackles

Misc straps and pulleys

Lighting

GE Nighthawk LED (re-branded Trucklights)

30" LED Light Bar

2" LED Spot Lights

Rims and Tires

Black Rock 15x8

Goodyear MT/R Kevlar 35x12.50R15

Dyna beads

Now, let me rewind a bit and start things off from the begin...again...for the second time.

I guess I'll do a short sum up of my Jeeps life and detail the actual build over the past two years or so to get everyone up to speed.

My Jeep started life as a 98 Wrangler Sport with a no name 4 inch lift and 33'' Futura Dakota RVT

Over time I did the normal stuff we all do, front and rear bumpers, rocker guards, suspension, exhaust, tires etc... and it looked like this.

It was around this time that my weekly routine was to get to work early to weld my control arms back on my frame or axle...which ever one decided to rip out that day, gotta love New England and our wonderful rust. After doing this a few to many times my awesome wife gave me the green light to, as she put it "do what you do", and so the work began.

My build so far is looking like this...

Frame

2000

Completely stripped

Coated inside and out with Rust Bullet

New motor mounts

New front track bar mount

New steering linkage mount

Newly fabed rear control arm mounts

Reinforced rust prone areas of frame

New transfer case nutserts

New Classic Tube SS brake lines

Motor

4.6L I-6

4.2 Crank

Brown Dog MML

Icon IC944 .30 pistons

Comp Cams 68-232-4

Mopar performance valve springs / Retainers - 5249464 / 4452032

Mopar performance head gasket - 4529242

Arp head studs

Melling oil pump

62mm TB

Fuel Pump, lines, Ford 24lb Injectors

FAL Fan

Aluminum Radiator

Header

Banks Exhaust

Hi Flow cat

New Gaskets

New Bearings

Custom mounted Amsoil cone filter w/pre-filter

Transmission/Transfer Case

Advanced Adapters SYE

Advanced Adapters Braided Stainless Clutch Line

Novak Transfer Case Shifter

Tom Woods Rear Drive Shaft

Suspension

OME 2.5 HD springs

OME L series shocks

JKS Control arms upper and Lower

JKS Quicker Discos

TNT Front track bar (with replacement frame bracket)

Rokmen .5 body lift

Rokmen bump stops extensions

Rokmen rear spring relocator kit

New bumper jounces

Axles

Front

2000 HP Dana 30

4.10

Solid differential cover

Lube locker

New upper control arm bushings

Gusseted lower control arm mounts and upper control arm mount

New Rotors and Pads

SS Brake Lines

- locker, RCV's, sleeves, Artec truss (ordered), C Gussets (ordered), Currie steering, Vanco BBK

Rear

1999 Ford 8.8

Ford Racing LSD Clutch Packs

4.10

Solid differential cover

Lube locker

New Rotors and Pads

Currie 8.8 brake line kit

Artec Truss

Yukon 8.8 Axles

- Locker

Armor

Rokmen HiLine Tube Fender

Rokmen Stryker Steel Corners

Rokmen Transfer Case Skid

Rokmen Gas Tank Skid

Rokmen Rocker Guards

Rokmen Power Steering Skid

Poison Spyder BFH II Rear Bumper

Mopar Front Rock Bumper

Recovery

Warn M8000-s

Front & Rear Shackles

Misc straps and pulleys

Lighting

GE Nighthawk LED (re-branded Trucklights)

30" LED Light Bar

2" LED Spot Lights

Rims and Tires

Black Rock 15x8

Goodyear MT/R Kevlar 35x12.50R15

Dyna beads

Now, let me rewind a bit and start things off from the begin...again...for the second time.

Last edited: