Frogmech

-

So I noticed a rather large wet spot on the underside of my jeep that I hadn't noticed before.

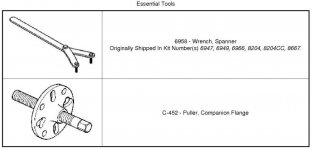

Seems to be the rear pinion seal leaking. Did some searching on this fine site and found out it shouldn't be that difficult to do. So I'm going to do it.

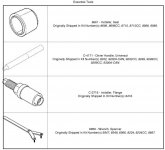

Judging by the parts break down and some reading, it seems simple enough.

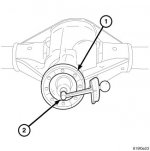

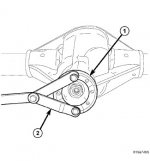

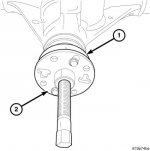

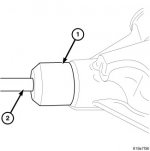

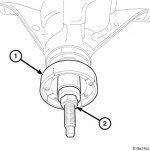

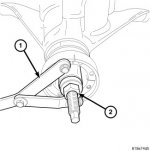

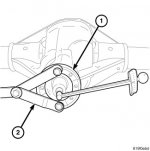

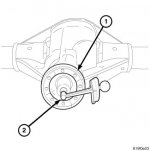

Remove the nut (1), washer (2), flange (3), slinger (4) and seal (5).

-What size are the drive shaft flange bolts? Re-installation torque?

-What size is the flange retaining nut? Re-installation torque?

-Will I need a puller to get the flange off?

-What the hell is a slinger and should I replace it? (Part 4 on the break down)

I also saw some seepage from the rear diff cover. It would seem like a great time to remove it, clean the gears and re-seal while I'm under. (As a side note, I plan on changing all the fluids in all the components after the big job is finished)

-Anyone want to recommend the best cleaning method/chemicals? My thought is brake cleaner unless there are other seals that might not get along well with brake cleaner.

Lastly, please tell me, from your experiences, what I have missed and what potential pitfalls I should avoid.

Thanks in advance to everyone who might offer up advice or assistance!

Seems to be the rear pinion seal leaking. Did some searching on this fine site and found out it shouldn't be that difficult to do. So I'm going to do it.

Judging by the parts break down and some reading, it seems simple enough.

Remove the nut (1), washer (2), flange (3), slinger (4) and seal (5).

-What size are the drive shaft flange bolts? Re-installation torque?

-What size is the flange retaining nut? Re-installation torque?

-Will I need a puller to get the flange off?

-What the hell is a slinger and should I replace it? (Part 4 on the break down)

I also saw some seepage from the rear diff cover. It would seem like a great time to remove it, clean the gears and re-seal while I'm under. (As a side note, I plan on changing all the fluids in all the components after the big job is finished)

-Anyone want to recommend the best cleaning method/chemicals? My thought is brake cleaner unless there are other seals that might not get along well with brake cleaner.

Lastly, please tell me, from your experiences, what I have missed and what potential pitfalls I should avoid.

Thanks in advance to everyone who might offer up advice or assistance!