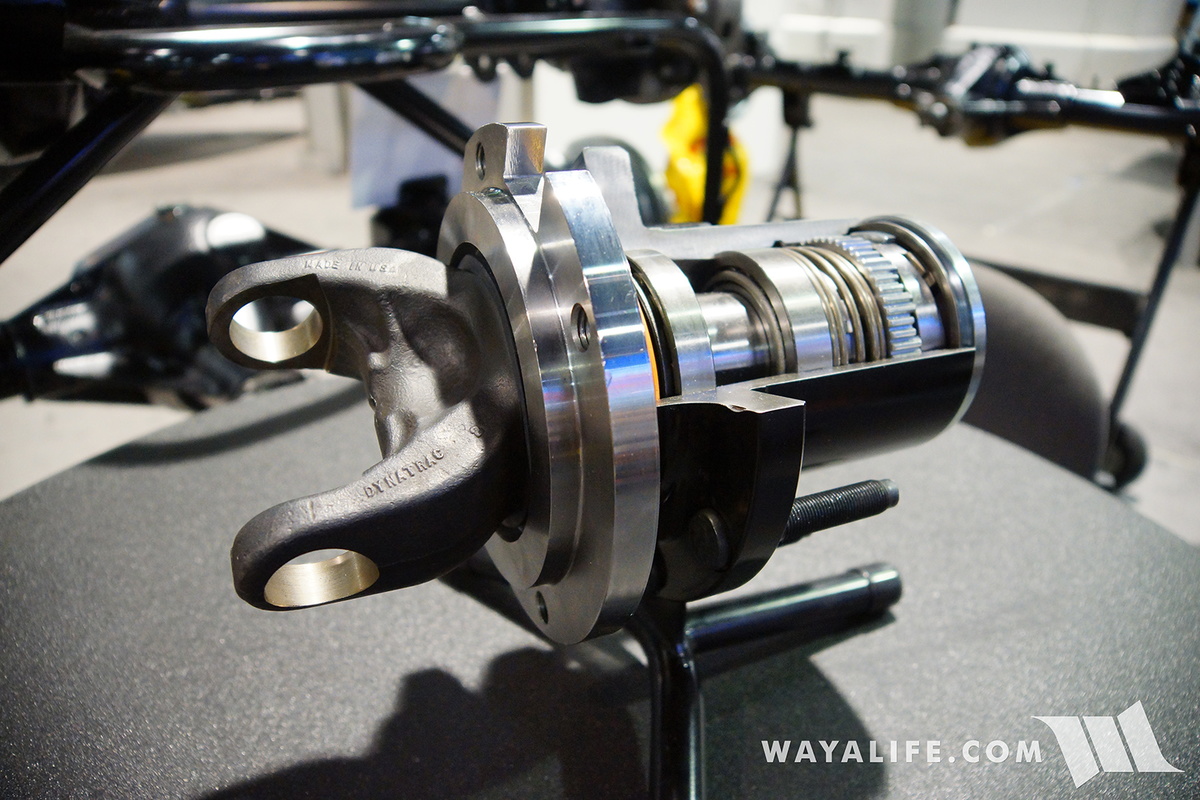

This is the fourth of 5 exclusive press releases that Cindy and I got from Dynatrac at the 2016 SEMA show. As you will see, this is an official release of their all new DynaLoc hub that gives their XD60 a hub-to-hub 40-spline strength with positive engagement and with a super low profile. Check it out!

New DynaLoc™ Hub Gives ProRock XD60™ Hub-to-Hub 40-Spline Strength with Positive Engagement, Low-Profile and 1/8-Turn Engagement

• Newest version of DynaLoc™ hub provides 40-spline strength for use with Dynatrac the ProRock XD60™ and ProRock 80™ front axle housings

• All DynaLoc hubs are three times stronger than competing locking hubs

• Unique design won’t allow hubs to disengage under high torque loads

• Low profile of DynaLoc hubs makes them less prone to trail damage

• 1/8-turn engagement is easy, positive and sure

• 100 percent made in the USA

Las Vegas – The new DynaLoc™ 40-spline hub from Dynatrac brings complete hub-to-hub 40-spline strength to ProRock XD60™ and ProRock 80™ front axles. The Dynatrac DynaLoc hub design has stood apart from competitors since it was introduced in 2006, boasting more strength and unique features than any locking hub in the past 35 years. Dynatrac’s new 40-spline version sets new benchmarks for strength and durability, and further widens the lead DynaLoc locking hubs have over other brands. DynaLoc hubs are 100 percent made in the USA.

The Dynatrac DynaLoc 40-spline hubs are part of a complete 40-spline 1550 package for the ProRock XD60 and ProRock 80 front-axle assemblies, providing customers with unmatched strength from hub-to-hub. The key components in this ultra-strong package include:

• New 40-spline DynaLoc hubs. In addition to larger and stronger internals designed specifically for a 40-spline outer axle, DynaLoc hubs are more than three times stronger than competing hubs, and with a unique gear design that won’t disengage under high torque load. They feature a low profile, keeping them tucked farther inside the wheels for more protection from trail damage. The locking mechanism also requires only an 1/8 turn to fully engage and disengage.

• Dynatrac axle shafts are made from 4340 chromoly steel, and feature a proprietary heat-treating process to give them optimal torsional strength while maintaining toughness and ductility to absorb shock loads that could damage differentials and ring-and-pinion gears. The one-piece forgings add significant reinforcement around the axle joint caps to protect against deformation under intense loads, a leading cause of steering-joint failure. The steering joints are 1550, the largest available in the industry. Steering angles up to 50 degrees are attainable with these Dynatrac shafts.

• Dynatrac 1550 LT® wheel ends are lightweight wheel ends that provide clearance to swing the massive shafts and steering joints. To facilitate service, the 1550 LT wheel ends are designed so that the entire shaft assembly can be slid in and out without the knuckle having to be removed from the end of the axle housing.

• A 40-spline ARB Air Locker, exclusively available through Dynatrac. This version of the ARB Air Locker has been engineered to accept 40-spline axle shafts and oversized Dynatrac ProRock XD60 carrier bearings. It is also equipped with the industry’s first oversized carrier bearing trunnion, which will not deform or cone-out under severe loads.

This combination builds upon the unique strength characteristics that made the ProRock XD60 the strongest and lightest axle in its class. And no axle matches the ground clearance provided by the patented ProRock® design.

New DynaLoc™ Hub Gives ProRock XD60™ Hub-to-Hub 40-Spline Strength with Positive Engagement, Low-Profile and 1/8-Turn Engagement

• Newest version of DynaLoc™ hub provides 40-spline strength for use with Dynatrac the ProRock XD60™ and ProRock 80™ front axle housings

• All DynaLoc hubs are three times stronger than competing locking hubs

• Unique design won’t allow hubs to disengage under high torque loads

• Low profile of DynaLoc hubs makes them less prone to trail damage

• 1/8-turn engagement is easy, positive and sure

• 100 percent made in the USA

Las Vegas – The new DynaLoc™ 40-spline hub from Dynatrac brings complete hub-to-hub 40-spline strength to ProRock XD60™ and ProRock 80™ front axles. The Dynatrac DynaLoc hub design has stood apart from competitors since it was introduced in 2006, boasting more strength and unique features than any locking hub in the past 35 years. Dynatrac’s new 40-spline version sets new benchmarks for strength and durability, and further widens the lead DynaLoc locking hubs have over other brands. DynaLoc hubs are 100 percent made in the USA.

The Dynatrac DynaLoc 40-spline hubs are part of a complete 40-spline 1550 package for the ProRock XD60 and ProRock 80 front-axle assemblies, providing customers with unmatched strength from hub-to-hub. The key components in this ultra-strong package include:

• New 40-spline DynaLoc hubs. In addition to larger and stronger internals designed specifically for a 40-spline outer axle, DynaLoc hubs are more than three times stronger than competing hubs, and with a unique gear design that won’t disengage under high torque load. They feature a low profile, keeping them tucked farther inside the wheels for more protection from trail damage. The locking mechanism also requires only an 1/8 turn to fully engage and disengage.

• Dynatrac axle shafts are made from 4340 chromoly steel, and feature a proprietary heat-treating process to give them optimal torsional strength while maintaining toughness and ductility to absorb shock loads that could damage differentials and ring-and-pinion gears. The one-piece forgings add significant reinforcement around the axle joint caps to protect against deformation under intense loads, a leading cause of steering-joint failure. The steering joints are 1550, the largest available in the industry. Steering angles up to 50 degrees are attainable with these Dynatrac shafts.

• Dynatrac 1550 LT® wheel ends are lightweight wheel ends that provide clearance to swing the massive shafts and steering joints. To facilitate service, the 1550 LT wheel ends are designed so that the entire shaft assembly can be slid in and out without the knuckle having to be removed from the end of the axle housing.

• A 40-spline ARB Air Locker, exclusively available through Dynatrac. This version of the ARB Air Locker has been engineered to accept 40-spline axle shafts and oversized Dynatrac ProRock XD60 carrier bearings. It is also equipped with the industry’s first oversized carrier bearing trunnion, which will not deform or cone-out under severe loads.

This combination builds upon the unique strength characteristics that made the ProRock XD60 the strongest and lightest axle in its class. And no axle matches the ground clearance provided by the patented ProRock® design.