Melosh (tennis pro)

New member

Earlier today I installed an Adams rear driveshaft on my 2dr. The install went well (it was my first time) and I took it for about a 30 mile drive after. I noticed a slight vibration (seemed to be the worst between 20-40 mph).

I wasn't too concerned, I assumed it was because of my pinion angle. To fix this issue, when I got home I installed some rock krawler rear uppers (I'd purchased them earlier bc of advice I'd gotten up here).

I set them to the lengths that were in the instructions (17 9/16"). I used a floor jack underneath the pinion in order to adjust it a little so I could get the new arms installed.

After installing the arms, I went on a quick test drive. I probably drove less than 5 miles. I could definitely hear and feel a stronger vibration and it seemed to be worse when I took my foot off the gas, before hitting the brakes...kinda, while it was coasting...and it happened pretty much the entire drive.

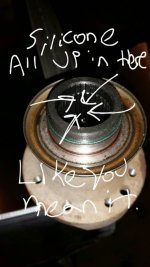

When I got home I noticed this (see pics).

I'm wondering if there's something I could've done while installing the arms to "break something"? Or I'm thinking that maybe I didn't tighten the rear pinion nut down enough when doing the ds install?

Sorry this question is so long, just trying to give the experts all the information. Any thoughts/opinions would be greatly appreciated.

Thx

Sent from my iPhone using WAYALIFE mobile app

I wasn't too concerned, I assumed it was because of my pinion angle. To fix this issue, when I got home I installed some rock krawler rear uppers (I'd purchased them earlier bc of advice I'd gotten up here).

I set them to the lengths that were in the instructions (17 9/16"). I used a floor jack underneath the pinion in order to adjust it a little so I could get the new arms installed.

After installing the arms, I went on a quick test drive. I probably drove less than 5 miles. I could definitely hear and feel a stronger vibration and it seemed to be worse when I took my foot off the gas, before hitting the brakes...kinda, while it was coasting...and it happened pretty much the entire drive.

When I got home I noticed this (see pics).

I'm wondering if there's something I could've done while installing the arms to "break something"? Or I'm thinking that maybe I didn't tighten the rear pinion nut down enough when doing the ds install?

Sorry this question is so long, just trying to give the experts all the information. Any thoughts/opinions would be greatly appreciated.

Thx

Sent from my iPhone using WAYALIFE mobile app