Exodus 4x4

New member

A customer dropped off his JLUR yesterday so we could install an EVO 2.5” Overland boost kit. While removing some of the factory parts we noticed some of the welds on the frame seam looked, a little porous.

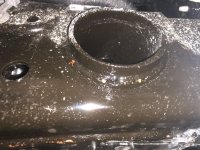

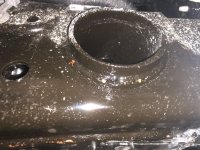

So that prompted us to start looking around the rest of the frame and sure enough we found several places where the beads were riddled with porosity.

In some places the welds didn’t even contact the frame and ZERO fusion occurred. I know it’s hard to make out in the picture but this is the spring perch on the passenger side.

I’m well aware that these are welded together by robots and no they aren’t perfect. I’m also well aware that this is something that has happened on previous models. However, this is 2018 and we should expect better quality control out of auto manufactures, especially when paying this much for a vehicle.

The customer is pretty upset and wants them to trade him out for another, but we know that’s not going to happen. I told him he needs to at least take it to the dealer and have it documented in case there is ever an issue. I took a ride down to the dealer to look over some of the others and see if this is a common issue with the JL and it doesn’t look to be.

Just be aware of what you’re buying and thoroughly look over them. Just like all first year productions there are going to be issues like this. No sense in buying a problem when the one next to it might not have the same issues.

Sent from my iPhone using WAYALIFE mobile app

So that prompted us to start looking around the rest of the frame and sure enough we found several places where the beads were riddled with porosity.

In some places the welds didn’t even contact the frame and ZERO fusion occurred. I know it’s hard to make out in the picture but this is the spring perch on the passenger side.

I’m well aware that these are welded together by robots and no they aren’t perfect. I’m also well aware that this is something that has happened on previous models. However, this is 2018 and we should expect better quality control out of auto manufactures, especially when paying this much for a vehicle.

The customer is pretty upset and wants them to trade him out for another, but we know that’s not going to happen. I told him he needs to at least take it to the dealer and have it documented in case there is ever an issue. I took a ride down to the dealer to look over some of the others and see if this is a common issue with the JL and it doesn’t look to be.

Just be aware of what you’re buying and thoroughly look over them. Just like all first year productions there are going to be issues like this. No sense in buying a problem when the one next to it might not have the same issues.

Sent from my iPhone using WAYALIFE mobile app