JeepinLife

Caught the Bug

After doing some poking around before changing out the seals on my front axle it seemed like a few people had some similar questions as me. So I thought I'd try to cover the steps I took to replace the seals. Hope some find this helpful.. Or just funny to read since it's my first write up if you can call it that. I'll try to answer any questions people may have on doing this. It's not hard to do at all. Or maybe others can give better insight on certain steps.

Reason we're doing this:

These are the two seals available for the front 44. I went with the seal on the right ending in AC.

1) lift front of jeep and set on jack stands, secure jeep and remove front tires.

You will also need to remove the tie rod.

2) remove brake caliper mounts and secure calipers out of the way.

3) remove the three bolts to the hub bearing.

4) remove the speed sensor.

5) remove axle shaft through the knuckle. You can put a punch through the u joint and catch it on the knuckle to zip off the axle nut. Or do it before brakes are off.

6) pull the diff drain plug and drain fluid.

7) remove diff cover.

8) mark the 4 bearing cap bolts and the position of the caps. It's important that they go back in the same place. The caps may have some identifying marks stamped on them and stamped on the housing.

9) remove the bearing cap bolts: mine were on so tight that they gouged into the retainer on the right side and bent it while the bolts came out so watch out for this. When you pull the bolts the carrier will be ready to come out so have a hand ready to hold it. Mine came out just by pulling on it with my hands, I've heard some people have to pry them out. Slowly remove the carrier from the housing to help keep track of the shims on either side, I only had one shim per side so it wasn't to hard. You will also have to disconnect the wires running from the locker coil to the plug that goes through the top of the diff. Once out I placed the carrier, bearings caps, bolts and shims on a piece of cardboard labeled pax and driver.

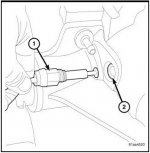

10) using a tool of your choice, we used a piece of threaded rod with washers and nuts holding a socket on the end and punched out the old seals. You're going to slide the tool you create in the axle shaft and punch the seals out in toward the inside of the diff housing.

11) clean the inside of the housing and where the seals sit well. I'd also take this time to clean out the axle tubes as well.

12) press in new seals. To do this we used a larger socket that fit the diameter of the flat on the seal and a wooden broom handle. We did the driver side first and ran the broom handle in from the pax side axle shaft. To do the pax side seal we switched to a 1/2" metal rod that we inserted through the driver side axle shaft and through the new seal. We wound up using the back of a 2 3/32 socket to press these in not the 1 5/8 pictured.

13) once the new seals are pressed in you need to pull out and secure the locker plunger before re installing the carrier. We used a aerosol can straw cut to size and tied fishing line to it so we could yank it out once the carrier was back in. If you don't do this you will most likely bend the plunger when re installing the carrier.

View attachment 191501

View attachment 191502

14) now you can re install the carrier. Since we only had one shim per side I oiled up where they sat in the housing so they would stick there. Then carefully placed the carrier into position and plug in the plug as you set the carrier back in. You may be able to plug it in after if you have small fingers. Be sure to set the retainer on the right bearing cap and tighten down the 4 bolts. Check your shims and pull the string out that's connected to the straw.

15) put the diff cover back on, check you put the drain plug back in and re install everything in the reverse order.

Reason we're doing this:

These are the two seals available for the front 44. I went with the seal on the right ending in AC.

1) lift front of jeep and set on jack stands, secure jeep and remove front tires.

You will also need to remove the tie rod.

2) remove brake caliper mounts and secure calipers out of the way.

3) remove the three bolts to the hub bearing.

4) remove the speed sensor.

5) remove axle shaft through the knuckle. You can put a punch through the u joint and catch it on the knuckle to zip off the axle nut. Or do it before brakes are off.

6) pull the diff drain plug and drain fluid.

7) remove diff cover.

8) mark the 4 bearing cap bolts and the position of the caps. It's important that they go back in the same place. The caps may have some identifying marks stamped on them and stamped on the housing.

9) remove the bearing cap bolts: mine were on so tight that they gouged into the retainer on the right side and bent it while the bolts came out so watch out for this. When you pull the bolts the carrier will be ready to come out so have a hand ready to hold it. Mine came out just by pulling on it with my hands, I've heard some people have to pry them out. Slowly remove the carrier from the housing to help keep track of the shims on either side, I only had one shim per side so it wasn't to hard. You will also have to disconnect the wires running from the locker coil to the plug that goes through the top of the diff. Once out I placed the carrier, bearings caps, bolts and shims on a piece of cardboard labeled pax and driver.

10) using a tool of your choice, we used a piece of threaded rod with washers and nuts holding a socket on the end and punched out the old seals. You're going to slide the tool you create in the axle shaft and punch the seals out in toward the inside of the diff housing.

11) clean the inside of the housing and where the seals sit well. I'd also take this time to clean out the axle tubes as well.

12) press in new seals. To do this we used a larger socket that fit the diameter of the flat on the seal and a wooden broom handle. We did the driver side first and ran the broom handle in from the pax side axle shaft. To do the pax side seal we switched to a 1/2" metal rod that we inserted through the driver side axle shaft and through the new seal. We wound up using the back of a 2 3/32 socket to press these in not the 1 5/8 pictured.

13) once the new seals are pressed in you need to pull out and secure the locker plunger before re installing the carrier. We used a aerosol can straw cut to size and tied fishing line to it so we could yank it out once the carrier was back in. If you don't do this you will most likely bend the plunger when re installing the carrier.

View attachment 191501

View attachment 191502

14) now you can re install the carrier. Since we only had one shim per side I oiled up where they sat in the housing so they would stick there. Then carefully placed the carrier into position and plug in the plug as you set the carrier back in. You may be able to plug it in after if you have small fingers. Be sure to set the retainer on the right bearing cap and tighten down the 4 bolts. Check your shims and pull the string out that's connected to the straw.

15) put the diff cover back on, check you put the drain plug back in and re install everything in the reverse order.

Last edited: