Strodinator

Caught the Bug

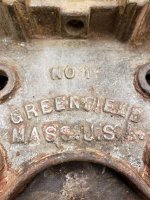

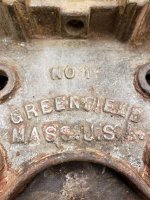

Not Jeep related but I'm having a great time doing it. I inherited a few tools from my great-grandfather after he passed 8 years or so ago. One of them was a really nice pipe vise. Made in Greenfield Massachusetts it's in excellent shape just needs cleaning up and a recoating. I'm taking it apart and restoring it best I can so I can actually use it.

Sent from my SM-G960W using WAYALIFE mobile app

Sent from my SM-G960W using WAYALIFE mobile app