Sharkey

Word Ninja

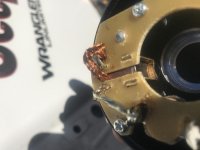

If you take the plastic intake disc off of the compressors you can see the internals sucking in air. One is working, one is not.What do you mean that only one of the compressors is working? How can you tell? As far as the ground, no ground should cause an engine light.

When I undid the ground nut closest to the air intake, I heard what sound like a starter clicking. It was like the existing ground was no longer grounded. (Yes, I was shortcutting and didn’t unhook the battery first, but I figured undoing a ground bolt wasn’t going to throw anything fits).

Jeep is driving fine and I don’t notice anything weird.