View attachment 206989

Possible Causes

BATTERY CABLE HIGH RESISTANCE

BATTERY CABLES

TRANSMISSION IS NOT READING THE PROPER RANGE (AUTO) OR CLUTCH SWITCH IS NOT READING THE PROPER STATUS (MANUAL)

OPEN FUSED BATTERY (+) CIRCUIT

STARTER COIL DRIVER (INTERNAL TIPM)

SKREEM CODES PRESENT

STARTER MOTOR

STARTER RELAY

(T752) STARTER RELAY CONTROL CIRCUIT OPEN

(T752) STARTER RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

(T750) STARTER RELAY OUTPUT CIRCUIT OPEN

MECHANICAL PROBLEM

POWERTRAIN CONTROL MODULE

Diagnostic Test

1.BATTERY CABLES

NOTE: The battery must be fully charged before diagnosing a no crank condition.

1. Turn the ignition off.

2. Inspect the battery cables for corrosion, looseness or other problems.

Is there evidence of problems?

Yes

Repair as necessary. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 2

2.CHECK THE BATTERY CABLES FOR HIGH RESISTANCE

1. Using the service information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 Volt?

Yes

Replace the battery cable(s). Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 3

3.TIPM CAN BUS CODES PRESENT

1. With the scan tool, read the TIPM DTCs.

NOTE: If there are CAN BUS related problems the TIPM will not supply power to the Starter Relay coil.

Does the scan tool display any CAN Bus related DTCs in the TIPM?

Yes

(Refer to 28 - DTC-Based Diagnostics/MODULE, Totally Integrated Power (TIPM) - Diagnosis and Testing) for problems related to CAN Bus communication. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 4

4.CHECK THE TRANSMISSION OR CLUTCH STATUS

NOTE: If there are DTCs related to the Clutch switch or Neutral Safety Switch, perform the diagnostic procedure for those DTCs before continuing.

1. With the scan tool, read the status of the Transmission range (Auto) or Clutch Switch position (Manual).

NOTE: The Auto Transmission must be in Park/Neutral position and the Manual Transmission Clutch Switch must read Clutch depressed in order for the engine to crank.

Does the scan tool display as described above?

Yes

Go To 5

No

Diagnose and repair the Park/Neutral or Clutch Switch failure. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

5.CHECKING STARTER OPERATION

1. Turn the ignition off.

2. Remove the Starter Relay from the TIPM.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

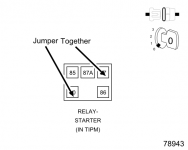

3. Momentarily jumper Starter Relay connector cavities 30 and 87 in the TIPM connector.

Did the engine crank?

Yes

Go To 6

No

Go To 11

6.STARTER RELAY

1. Install a known good relay in place of the Starter Relay.

2. Attempt to start the engine.

Does the engine crank?

Yes

Replace the Starter Relay. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 7

7.CHECK THE PCM POWERS AND GROUNDS

1. (Refer to 29 - Non-DTC Diagnostics/Drivability - Diesel - Diagnosis and Testing) and perform the Checking the PCM POWER AND GROUND diagnostic procedure.

Were any problem found with the PCM powers and grounds?

Yes

Repair as necessary. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 8

8.CHECK THE STARTER COIL DRIVE CIRCUIT (INTERNAL TIPM)

1. Turn the ignition off.

2. Remove the Starter Relay from the TIPM.

3. Using a 12-Volt test light connected to ground, check the Starter Coil Driver circuit in the Starter Relay connector while turning the ignition switch to the START position.

Does the test light illuminate with the ignition switch in the START position?

Yes

Go To 9

No

Check the TIPM ignition supply circuits and fuses. If TIPM fuses and ignition supply circuits are ok, replace the TIPM. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

9.CHECK THE (T752) STARTER RELAY CONTROL CIRCUIT FOR A SHORT TO VOLTAGE

1. Turn the ignition off.

2. Disconnect the PCM harness connectors.

3. Remove the ASD Relay from the TIPM.

4. Using a jumper wire, connect ASD Relay connector cavities 30 and 87 in the TIPM.

5. Turn the ignition on.

6. Measure the voltage of the (T752) Starter Relay Control circuit.

Is the voltage above 1.0 volt?

Yes

Repair the (T752) Starter Relay Control circuit for a short to voltage. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Go To 10

10.CHECK THE (T752) STARTER RELAY CONTROL CIRCUIT FOR AN OPEN

1. Turn the ignition off.

2. Remove the jumper wire and install the ASD Relay.

3. Measure the resistance of the (T752) Starter Relay Control circuit between the PCM harness connector and the Starter Relay connector in the TIPM.

Is the resistance below 5.0 ohms?

Yes

Replace the Powertrain Control Module in accordance with the service information. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

No

Repair the (T752) Starter Relay Control circuit for an open. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

11.CHECK THE FUSED B(+) CIRCUIT FOR AN OPEN

1. Using a 12-Volt test light connected to ground, check the Fused B(+) circuit in the Starter Relay connector in the TIPM.

Is the test light illuminated and bright?

Yes

Go To 12

No

Repair the Fused B(+) circuit for an open. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).

12.CHECK THE (T750) STARTER RELAY OUTPUT CIRCUIT FOR AN OPEN

1. Disconnect the (T750) Starter Relay Output wire from the Starter Solenoid.

2. Connect the (T750) Starter Relay Output wire (at the Starter) to ground.

3. Using a 12-Volt test light connected to 12-Volts, check the (T750) Starter Relay Output circuit at the Starter Relay connector in the TIPM.

Does the test light illuminate brightly?

Yes

Go To 13

No

Repair the (T750) Starter Relay Output circuit for an open. Perform the PCM VERIFICATION TEST. (Refer to 28 - DTC-Based Diagnostics/MODULE, Powertrain Control (PCM) - Standard Procedure).