The CV boot on your drive shaft is in a constant state of pinch. It WILL fail sooner than later and when it does, grease will spit out and you will see this on the bottom of your Jeep. After that, it'll only be a matter of time before the bearing fail. Once you start to hear them make a ratcheting sound, they're just about done. Just an FYI to know what to look for being that you want to keep your factory shaft.

Your rear coils look about right assuming your pinion angle has been corrected. This of course is totally unnecessary with factory rzeppa shafts. Regardless, it will not effect the way your Jeep handles.

What ever drift you're feeling has nothing to do with your axle being off centered. That has everything to do with your track bar and it's just the nature of the beast. Looking at your pics, it looks like your rear axle is shifted to the driver side? If that is correct, load up the rear end of your Jeep and it'll look more centered again.

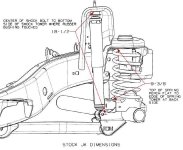

Your lower control arms should be the same length eye to eye. The front uppers should be set equal as well and until you have 4° of caster. In the rear, your pinion and output shaft should be parallel from the factory but if you're running an aftermarket shaft, the pinion should be set in line with your drive shaft. Of course, with an rzeppa shaft, it really doesn't matter too much.