You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beware!! - EVO Protek Skid Plates

- Thread starter OverlanderJK

- Start date

kevman65

Hooked

Before I make my comment, I want to give my qualification. I am a CWI (Certified Weld Inspector) with major experience in refineries and power houses. So that's out of the way.

By the looks of a couple of pictures where it's a clean shot and low glare, the tab steel itself is of poor quality. Appears to be stress cracks across the steel at the fracture point. Doesn't mean there isn't a problem. Who knows where else that batch of steel was used.

As to the weld, it is a fillet weld, so there is minimal penetration. It's the width (or height) of the weld that gives it it's strength.

I can't tell the thickness of the piece that the weld is still on, but going to venture it is thicker than the tabs are and that is why the fillet is wider(or taller) than the thickness of the tab steel.

Now, the only way to tell if the rest of the steel is good or bad, is to use NDT (non destructive testing) and the cost of that would probably be close to the cost of the part.

By the looks of a couple of pictures where it's a clean shot and low glare, the tab steel itself is of poor quality. Appears to be stress cracks across the steel at the fracture point. Doesn't mean there isn't a problem. Who knows where else that batch of steel was used.

As to the weld, it is a fillet weld, so there is minimal penetration. It's the width (or height) of the weld that gives it it's strength.

I can't tell the thickness of the piece that the weld is still on, but going to venture it is thicker than the tabs are and that is why the fillet is wider(or taller) than the thickness of the tab steel.

Now, the only way to tell if the rest of the steel is good or bad, is to use NDT (non destructive testing) and the cost of that would probably be close to the cost of the part.

OverlanderJK

Resident Smartass

It’s all 1/4”Before I make my comment, I want to give my qualification. I am a CWI (Certified Weld Inspector) with major experience in refineries and power houses. So that's out of the way.

By the looks of a couple of pictures where it's a clean shot and low glare, the tab steel itself is of poor quality. Appears to be stress cracks across the steel at the fracture point. Doesn't mean there isn't a problem. Who knows where else that batch of steel was used.

As to the weld, it is a fillet weld, so there is minimal penetration. It's the width (or height) of the weld that gives it it's strength.

I can't tell the thickness of the piece that the weld is still on, but going to venture it is thicker than the tabs are and that is why the fillet is wider(or taller) than the thickness of the tab steel.

Now, the only way to tell if the rest of the steel is good or bad, is to use NDT (non destructive testing) and the cost of that would probably be close to the cost of the part.

kevman65

Hooked

Then the fillet weld is excessive.It’s all 1/4”

OverlanderJK

Resident Smartass

Bullwinckle

Hooked

Damn that sucks. Looks like EVO may send you a new one or hope so.

Slimebones

Active Member

Seems like a clue.Looks like you may check your engine mounts. With one end connecting to the engine and the other connected to the frame something has to be moving excessively.

Speedy_RCW

Hooked

Looks like a heat affected zone failure to me. Probably cooled too fast as they pump these out of production.Before I make my comment, I want to give my qualification. I am a CWI (Certified Weld Inspector) with major experience in refineries and power houses. So that's out of the way.

By the looks of a couple of pictures where it's a clean shot and low glare, the tab steel itself is of poor quality. Appears to be stress cracks across the steel at the fracture point. Doesn't mean there isn't a problem. Who knows where else that batch of steel was used.

As to the weld, it is a fillet weld, so there is minimal penetration. It's the width (or height) of the weld that gives it it's strength.

I can't tell the thickness of the piece that the weld is still on, but going to venture it is thicker than the tabs are and that is why the fillet is wider(or taller) than the thickness of the tab steel.

Now, the only way to tell if the rest of the steel is good or bad, is to use NDT (non destructive testing) and the cost of that would probably be close to the cost of the part.

-AINOKEA-

Hooked

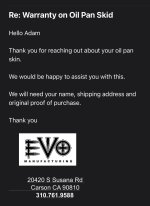

Interesting they need a proof of original purchase. I mean they don’t claim a lifetime warranty anywhere on their stuff but for something like this that’s clearly not a large scale incident…? Do ya warranty your stuff or not? Who cares who originally bought it.I emailed evo this morning and got this response. I don’t have the original receipt so we will see what they do. They didn’t respond after this so maybe they already have it taken care of or I’ll hear next week.

View attachment 375679

OverlanderJK

Resident Smartass

I kind of agree. And who keeps receipts of stuff like that for that long? I have not gotten a response back from them when I told them I didn’t have it and have not gotten a new skid yet. I guess I’ll reach back out next week.Interesting they need a proof of original purchase. I mean they don’t claim a lifetime warranty anywhere on their stuff but for something like this that’s clearly not a large scale incident…? Do ya warranty your stuff or not? Who cares who originally bought it.

Also, it was drop shipped from them so I guess it should be in their system too.

OverlanderJK

Resident Smartass

This was my thought.Looks like a heat affected zone failure to me. Probably cooled too fast as they pump these out of production.

DZRTJP

Active Member

Wow, sorry to hear & see that. Sure looks like metal failure. I'm thinking like the others, something is loose or broken to cause tension or flexing. Or maybe bolted up with the frame flexed somewhat instead of level? Though once in awhile, raw steel gets delivered that's not up to snuff.

I'm going to make sure I check mine, I actually have needed them for a couple boulders. I've no idea what brand they are. I just know the hole for the oil drain plug is awfully small for my hands.

(They were installed by a previous owner).

I'm going to make sure I check mine, I actually have needed them for a couple boulders. I've no idea what brand they are. I just know the hole for the oil drain plug is awfully small for my hands.

(They were installed by a previous owner).

OverlanderJK

Resident Smartass

I'm really sorry to hear it.Been two weeks and I had heard nothing from EVO, not even a response to tell me they were looking into it so I emailed this morning. This is the response I got. I guess I don’t have much faith now since they still need to “check with their team” two weeks later.

View attachment 376042

CalSgt

Hooked

I don't recall needing a receipt when they replaced my track bar bushings but I guess it was newer stuff and less expensive.Been two weeks and I had heard nothing from EVO, not even a response to tell me they were looking into it so I emailed this morning. This is the response I got. I guess I don’t have much faith now since they still need to “check with their team” two weeks later.

View attachment 376042

OverlanderJK

Resident Smartass

Yeah who knows. I haven’t searched too hard for their warranty policy but I did look at the page for the skid and it doesn’t say that. Just says lifetime. Maybe the bushing is because it was a known problem.I don't recall needing a receipt when they replaced my track bar bushings but I guess it was newer stuff and less expensive.

TrailHunter

Hooked

Why not just weld up some new tabs?

OverlanderJK

Resident Smartass

Has a warranty. Why would I not get it warrantied?Why not just weld up some new tabs?

TrailHunter

Hooked

Because you could have had it fixed and bolted back up 2 weeks ago.Has a warranty. Why would I not get it warrantied?