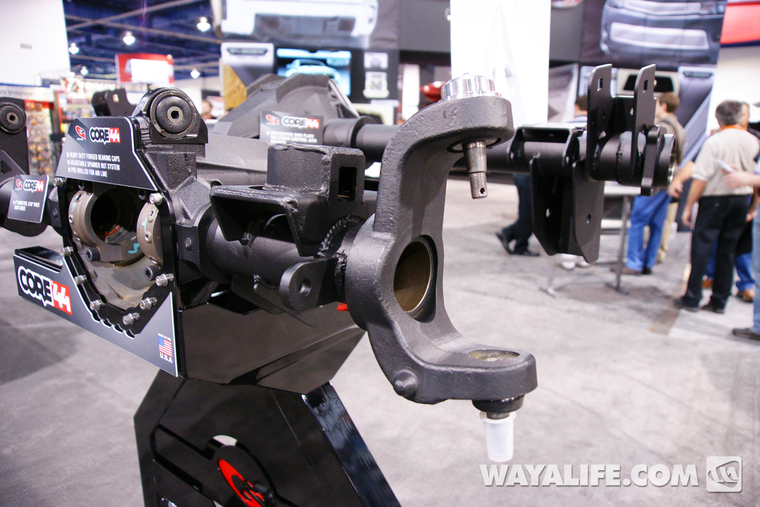

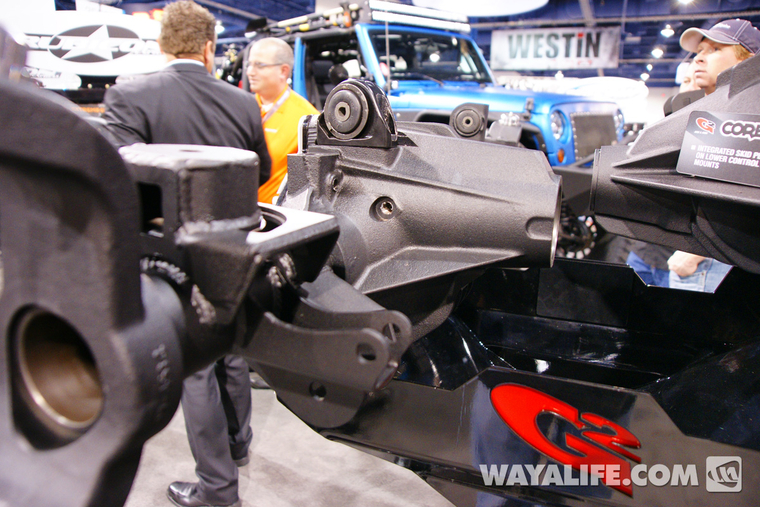

At the 2013 SEMA Show, G2 released their all new CORE 44 axle housings featuring 3" tubes that are 5/16" thick and aluminum differential covers. I am told that the housings are in fact Made in the USA with options to build the internal components with USA made products as well. Check it out...

It should be noted that the dip stick fill bolt will not be included on production model diff covers. Apparently, it was discovered that there were some clearance issues with aftermarket track bars and so the design has been modified...

Here is a shot of their made in the USA front axles but, I will note that not all of the ones on display actually said they were made in the USA - the ones you see here didn't but the one on their rig did...

Their overseas front shafts did come with full circle clips...

It should be noted that the dip stick fill bolt will not be included on production model diff covers. Apparently, it was discovered that there were some clearance issues with aftermarket track bars and so the design has been modified...

Here is a shot of their made in the USA front axles but, I will note that not all of the ones on display actually said they were made in the USA - the ones you see here didn't but the one on their rig did...

Their overseas front shafts did come with full circle clips...