In spite of what so many people on the internet will try and tell you, Dana 44 front axle shafts on a Jeep JK Wrangler Rubicon are NOT inherently weak and you do NOT need to go out and buy a set of expensive RCV shafts to prevent breaks. The problem with factory axle shafts is that they utilize c-clips to hold the bearing caps in place and over time, movement in the caps can cause the c-clips to work themselves free. Once the c-clips are gone, there's nothing left to hold the bearing caps in place and if they fall out, it's just a matter of time before the trunnions tear apart the ears of the yokes. That being said, a great solution to help prevent this from happening is to run a good set of chromoly shafts and u-joints with full circle clips, much like the kind that AlloyUSA makes. The full circle clips will not come free of the bearing caps and this alone will help prevent the number one cause of front axle shaft breaks. This video and the write-up below will show you just how easy it is to install a set of AlloyUSA X-Joints with full circle clips onto one of their chomoly front axle shafts.

NOTE: For the purpose of this install, I used a cheap shop press that I bought from Harbor Freight a long time ago. Using one will make this job a lot easier and you'll find it helpful to have for a variety of maintenance tasks. That being said, having one isn't required. You can still do this with a bench vice or u-joint press that you can borrow for free from Autozone or the like.

What you will need

• Dana 44 Chromoly Front Axle Shafts

• AlloyUSA X-Joints

• 7mm Wrench

• Snap Ring Pliers

• Hammer

• Brass Hammer

• Flat/Rounded File

• Grease

• Grease Gun w/ Needle Fitting

• Bench Vice

• Shop Press

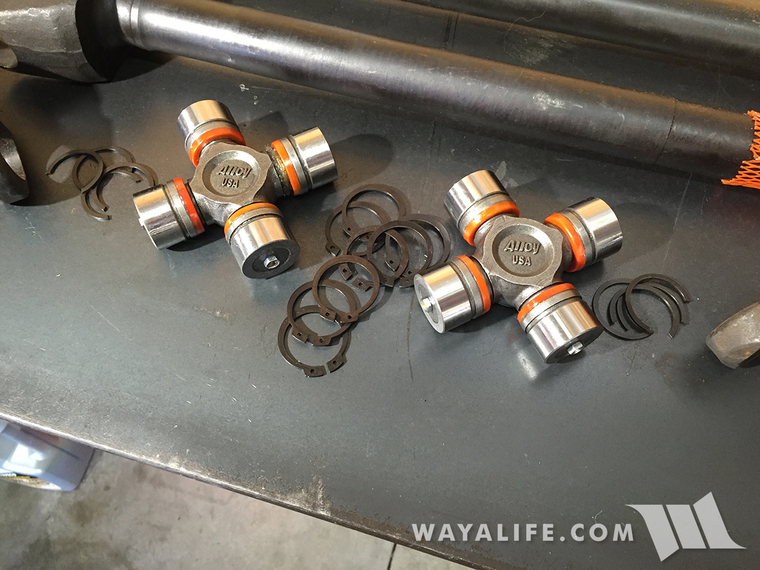

This is a shot of everything you will get with your AlloyUSA Dana 44 Chromoly Axle Shafts and X-Joints. As you will see, you will get both standard c-clips and full circle clips with the X-Joints.

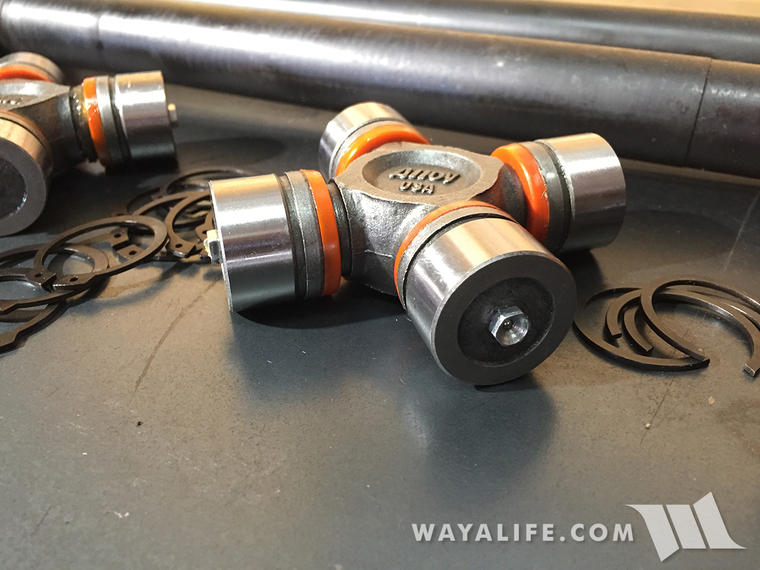

Here are a couple of close up shots of the AlloyUSA X-Joints. Notice that they do come with needle zerk fittings so that you can grease them.

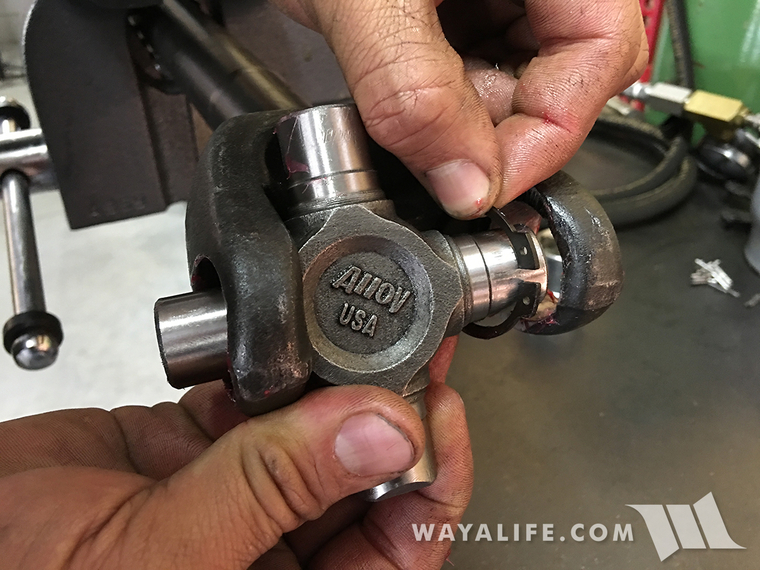

Here you can see how the axle yokes have clearance at the ears to allow for full circle clips.

This is a shot of what a full circle clip looks like compared to a standard c-clip.

Instructions

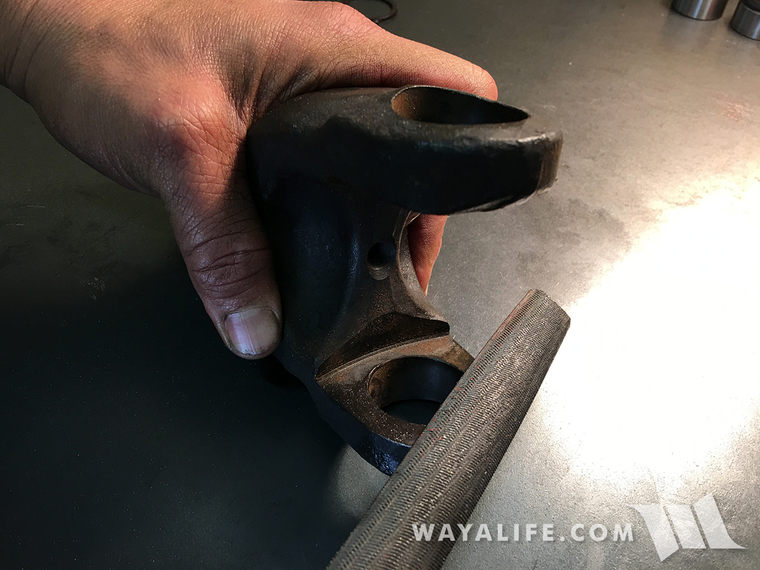

1. Take a flat file and use it to debur the yokes on both the axle shafts and stub shafts.

2. Take a rounded file and use it debur the edges of the yoke bores.

3. Thoroughly clean your work table and your axle shaft and make sure it's free of any contaminants. Then, take your passenger side axle shaft and apply a thin layer of grease to the insides of the yoke bores as shown.

4. Take one of your AlloyUSA X-Joints and remove the zerk fittings on the bearing caps using a 7mm wrench.

5. Carefully remove the bearing caps off making sure not to disturb or lose any of the needle bearings inside of them.

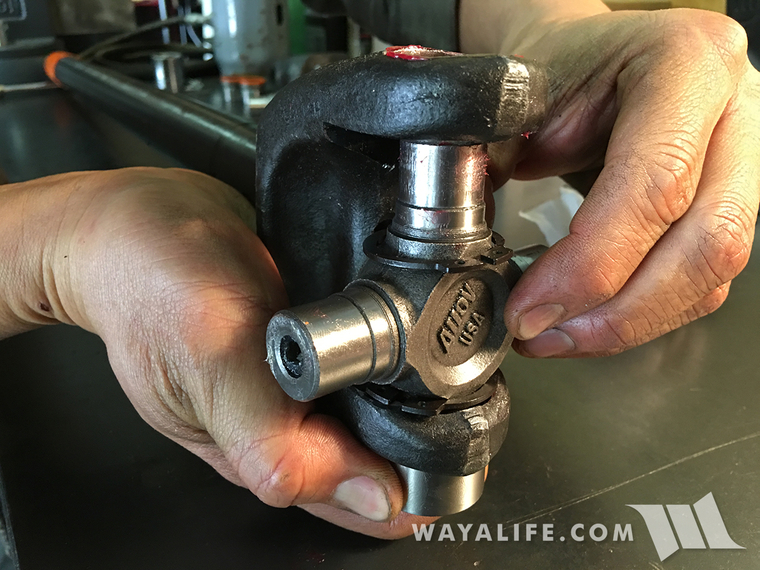

6. The AlloyUSA X-Joint have beveled ends on two of the trunnions and they are there to help make it easier to install onto the axle shaft yokes. Making sure that the AlloyUSA logo is facing out, put one end of the trunnion into the yoke bore, slip a full circle clip onto the opposite trunnion and then tilt it into the yoke bore as shown.

7. Again, pushing the X-Joint all the way into the yoke bore, slip a full circle clip onto the opposite trunnion.

8. Take one of the bearing caps and double check to make sure all the needle bearings are still in place.

9. Carefully insert the bearing cap into the axle yoke bore making sure that the X-Joint trunnion goes into it without disturbing the needle bearings.

10. Tap the yoke with a hammer to help seat the bearing cap below further into the bore. You don't need it to go in all the way but rather, just far enough to help ensure that the trunnion pointing up will start to engage the bearing cap as you install it on the opposite end.

11. Carefully insert a bearing cap into the opposite bore of the yoke being careful to go in straight and centered over the exposed trunnion.

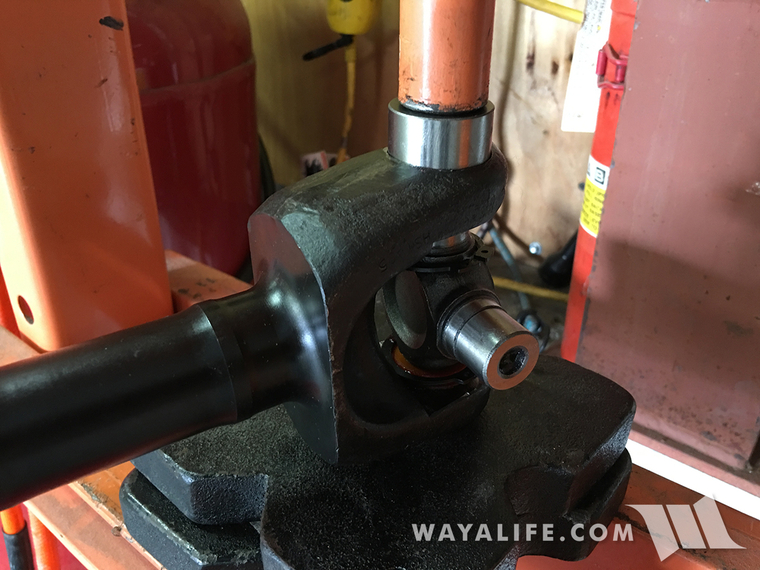

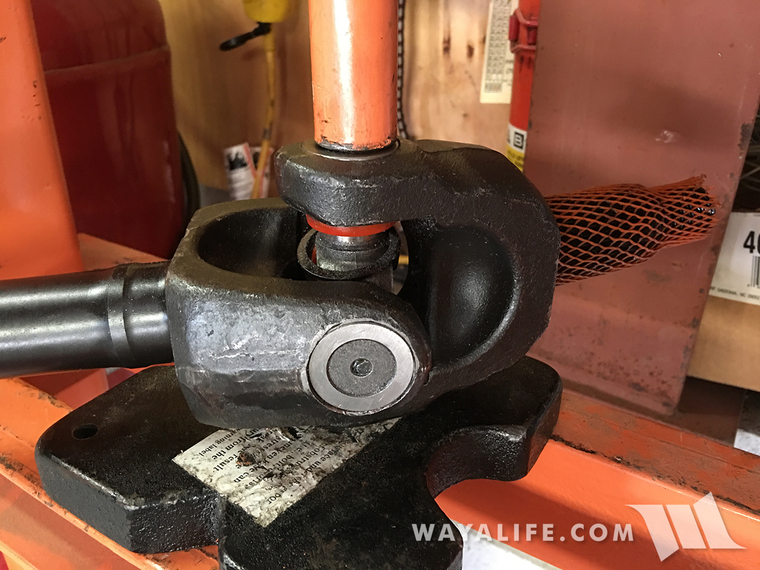

12. Use a shop press to press the bearing caps into the yoke as shown.

13. Place a couple of sockets that are slightly smaller than the bearing caps on top of and below them to help press them all the way in. They will need to be pressed in far enough to expose the groove where the full circle clips get seated.

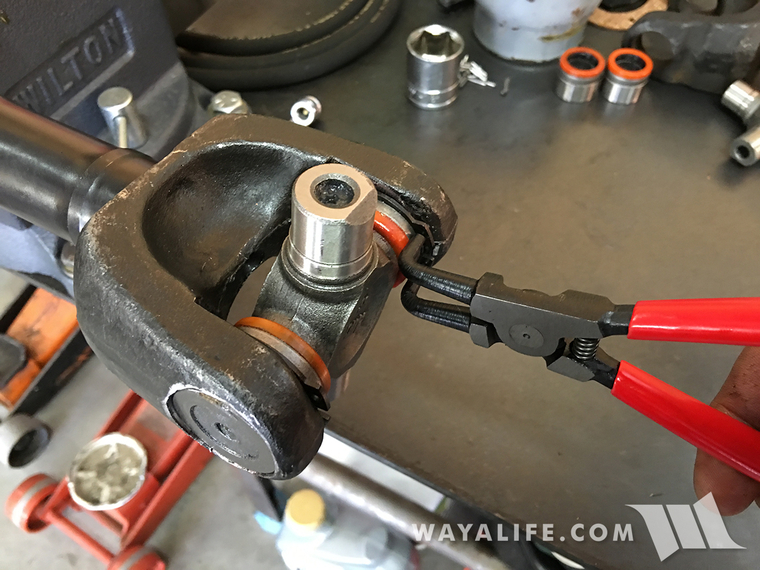

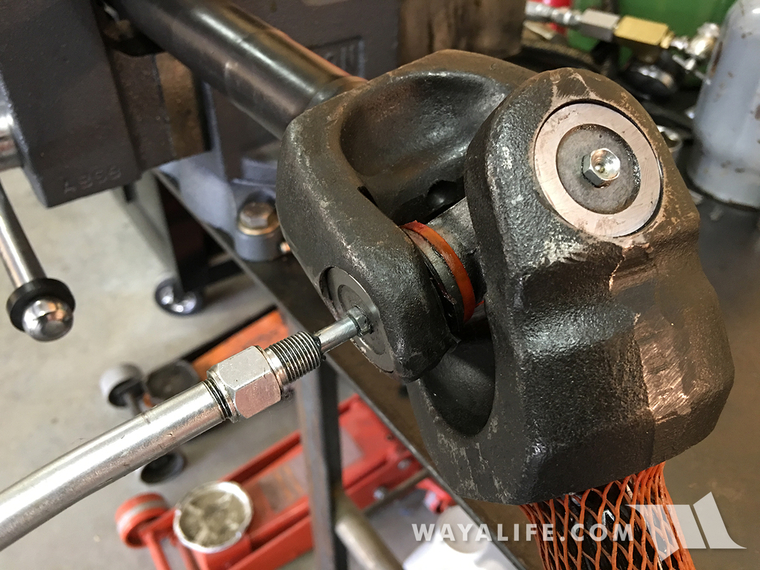

14. Remove the axle shaft from the press and then use snap ring pliers to install the full circle clips into the bearing cap groves as shown.

15. At this point, the X-Joint may feel tight and hard to rotate. Take a hammer and give each side of the yoke a solid hit as shown. This will ring things out and help to free everything up.

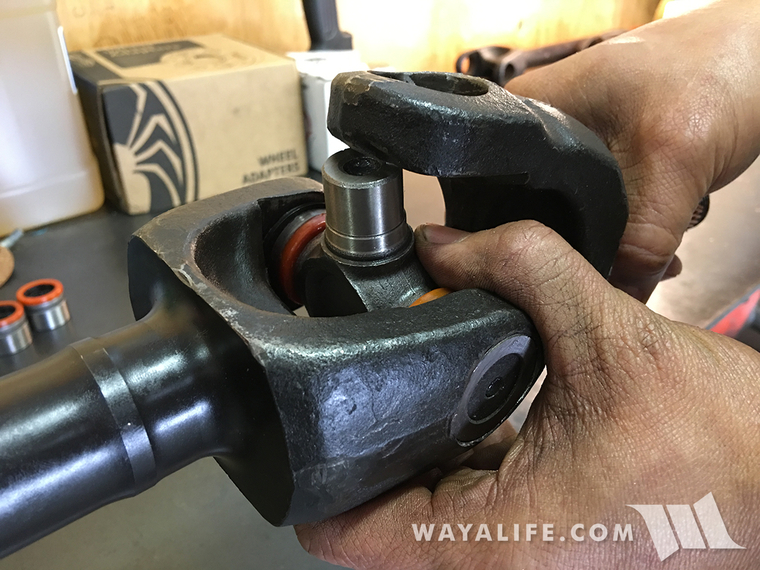

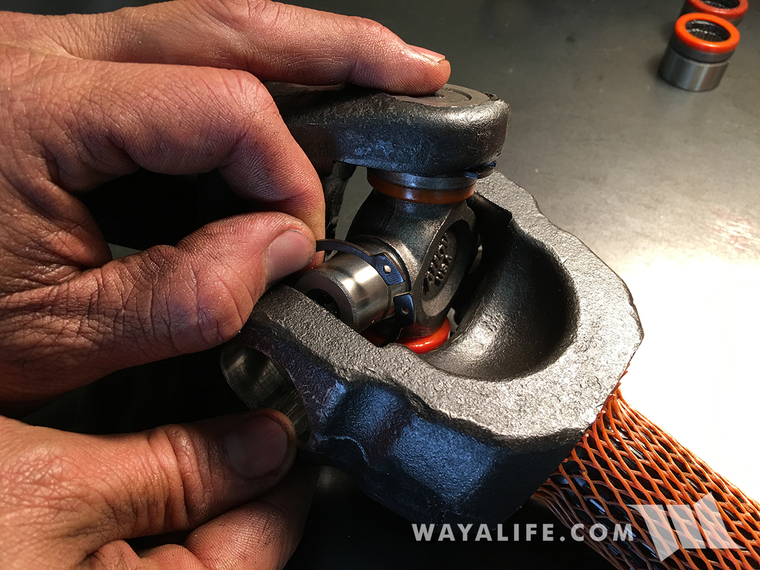

16. Take your axle shaft, place a full circle clip onto the exposed trunnion that's completely round and then slip it through the bore of the stub shaft yoke. Then, try to insert the beveled end into the opposite end as shown.

16. Even with the trunnion being beveled, you may find it difficult if not impossible to slip it into the stub shaft yoke. You may find it necessary to file down the edge of the stub shaft yoke a bit to help things out.

17. Once you've gotten both ends of the X-Joint in the bore of the stub shaft yoke, slip the last full circle clip onto the remaining trunnion.

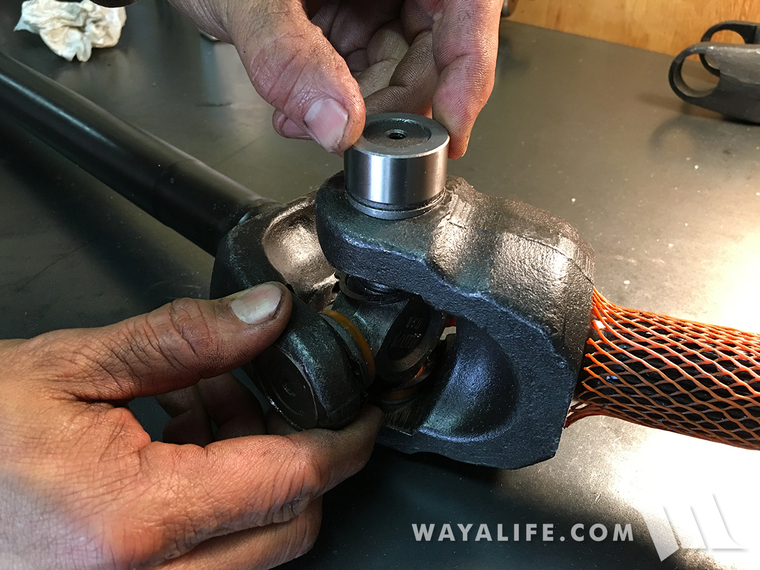

18. As you had before, take a bearing caps and double check to make sure all the needle bearings are still in place. Then, carefully insert the bearing cap into the stub shaft yoke bore making sure that the X-Joint trunnion goes into it without disturbing the needle bearings. Tap the yoke with a hammer to help seat the bearing cap below further into the bore.

19. Carefully insert a bearing cap into the opposite bore of the stub shaft yoke being careful to go in straight and centered over the exposed trunnion.

20. Take your axle back to the press and press the bearing caps into the stub shaft yoke as shown. As before, you can use a couple of sockets that are slightly smaller than the bearing caps to help press them all the way in. They will need to be pressed in far enough to expose the groove where the full circle clips get seated.

21. Remove the axle shaft from the press and then use snap ring pliers to install the full circle clips into the bearing cap groves as shown.

22. Again, take a hammer and give each side of the yoke a solid hit as shown. This will ring things out and help to free everything up.

23. Double check to make sure everything is moving freely.

24. Reinstall the zerk fittings onto the ends of the bearing caps and tighten them up with a 7mm wrench.

25. Use a grease gun with a needle fitting to grease all the bearing caps.

That's all there is to it. All you have to do is repeat the process on the driver side axle shaft. Here are a couple of shots of what your assembled passenger side AlloyUSA Dana 44 chromoly axle shaft with X-Joint u-joints should look like.

If you haven't already seen it, check out the accompanying installation video as it's a revised version of this write-up and contains a few useful steps that are a bit different. Also, if you're in need of a write-up to help you install your newly assembled axle shafts, click on the link below:

Jeep JK Wrangler Front Axle Shaft Removal & Replacement Write-Up + VIDEO

Please let me know if you have any questions.

NOTE: For the purpose of this install, I used a cheap shop press that I bought from Harbor Freight a long time ago. Using one will make this job a lot easier and you'll find it helpful to have for a variety of maintenance tasks. That being said, having one isn't required. You can still do this with a bench vice or u-joint press that you can borrow for free from Autozone or the like.

What you will need

• Dana 44 Chromoly Front Axle Shafts

• AlloyUSA X-Joints

• 7mm Wrench

• Snap Ring Pliers

• Hammer

• Brass Hammer

• Flat/Rounded File

• Grease

• Grease Gun w/ Needle Fitting

• Bench Vice

• Shop Press

This is a shot of everything you will get with your AlloyUSA Dana 44 Chromoly Axle Shafts and X-Joints. As you will see, you will get both standard c-clips and full circle clips with the X-Joints.

Here are a couple of close up shots of the AlloyUSA X-Joints. Notice that they do come with needle zerk fittings so that you can grease them.

Here you can see how the axle yokes have clearance at the ears to allow for full circle clips.

This is a shot of what a full circle clip looks like compared to a standard c-clip.

Instructions

1. Take a flat file and use it to debur the yokes on both the axle shafts and stub shafts.

2. Take a rounded file and use it debur the edges of the yoke bores.

3. Thoroughly clean your work table and your axle shaft and make sure it's free of any contaminants. Then, take your passenger side axle shaft and apply a thin layer of grease to the insides of the yoke bores as shown.

4. Take one of your AlloyUSA X-Joints and remove the zerk fittings on the bearing caps using a 7mm wrench.

5. Carefully remove the bearing caps off making sure not to disturb or lose any of the needle bearings inside of them.

6. The AlloyUSA X-Joint have beveled ends on two of the trunnions and they are there to help make it easier to install onto the axle shaft yokes. Making sure that the AlloyUSA logo is facing out, put one end of the trunnion into the yoke bore, slip a full circle clip onto the opposite trunnion and then tilt it into the yoke bore as shown.

7. Again, pushing the X-Joint all the way into the yoke bore, slip a full circle clip onto the opposite trunnion.

8. Take one of the bearing caps and double check to make sure all the needle bearings are still in place.

9. Carefully insert the bearing cap into the axle yoke bore making sure that the X-Joint trunnion goes into it without disturbing the needle bearings.

10. Tap the yoke with a hammer to help seat the bearing cap below further into the bore. You don't need it to go in all the way but rather, just far enough to help ensure that the trunnion pointing up will start to engage the bearing cap as you install it on the opposite end.

11. Carefully insert a bearing cap into the opposite bore of the yoke being careful to go in straight and centered over the exposed trunnion.

12. Use a shop press to press the bearing caps into the yoke as shown.

13. Place a couple of sockets that are slightly smaller than the bearing caps on top of and below them to help press them all the way in. They will need to be pressed in far enough to expose the groove where the full circle clips get seated.

14. Remove the axle shaft from the press and then use snap ring pliers to install the full circle clips into the bearing cap groves as shown.

15. At this point, the X-Joint may feel tight and hard to rotate. Take a hammer and give each side of the yoke a solid hit as shown. This will ring things out and help to free everything up.

16. Take your axle shaft, place a full circle clip onto the exposed trunnion that's completely round and then slip it through the bore of the stub shaft yoke. Then, try to insert the beveled end into the opposite end as shown.

16. Even with the trunnion being beveled, you may find it difficult if not impossible to slip it into the stub shaft yoke. You may find it necessary to file down the edge of the stub shaft yoke a bit to help things out.

17. Once you've gotten both ends of the X-Joint in the bore of the stub shaft yoke, slip the last full circle clip onto the remaining trunnion.

18. As you had before, take a bearing caps and double check to make sure all the needle bearings are still in place. Then, carefully insert the bearing cap into the stub shaft yoke bore making sure that the X-Joint trunnion goes into it without disturbing the needle bearings. Tap the yoke with a hammer to help seat the bearing cap below further into the bore.

19. Carefully insert a bearing cap into the opposite bore of the stub shaft yoke being careful to go in straight and centered over the exposed trunnion.

20. Take your axle back to the press and press the bearing caps into the stub shaft yoke as shown. As before, you can use a couple of sockets that are slightly smaller than the bearing caps to help press them all the way in. They will need to be pressed in far enough to expose the groove where the full circle clips get seated.

21. Remove the axle shaft from the press and then use snap ring pliers to install the full circle clips into the bearing cap groves as shown.

22. Again, take a hammer and give each side of the yoke a solid hit as shown. This will ring things out and help to free everything up.

23. Double check to make sure everything is moving freely.

24. Reinstall the zerk fittings onto the ends of the bearing caps and tighten them up with a 7mm wrench.

25. Use a grease gun with a needle fitting to grease all the bearing caps.

That's all there is to it. All you have to do is repeat the process on the driver side axle shaft. Here are a couple of shots of what your assembled passenger side AlloyUSA Dana 44 chromoly axle shaft with X-Joint u-joints should look like.

If you haven't already seen it, check out the accompanying installation video as it's a revised version of this write-up and contains a few useful steps that are a bit different. Also, if you're in need of a write-up to help you install your newly assembled axle shafts, click on the link below:

Jeep JK Wrangler Front Axle Shaft Removal & Replacement Write-Up + VIDEO

Please let me know if you have any questions.