LO_Rex

New member

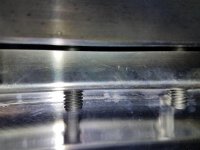

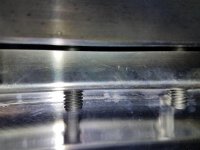

Anyone else have a gap in their ring and rim when running Coopers and Chamber Pros? The ring is torqued to spec and I still have a small gap between the rim an the ring. I am worried that i pull out the inserts if i keep cranking them down.

Sent from my SM-G930P using WAYALIFE mobile app

Sent from my SM-G930P using WAYALIFE mobile app