I think your answer here is right on point! Probably a bit to technical for the OP since he seems to be having trouble grasping the adjustment concept! I will add something positive and reiterate in the simplest terms why you should not attempt this:

View attachment 217199

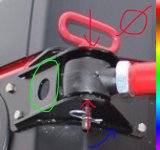

The blue arrow points to this bead looking thing called a weld. The weld of two perpendicular plates like shown is susceptible to cracking from fatigue when constant bending forces are applied perpendicular to the weld as shown with the red arrows. The stiffener, circled in green, is there to help prevent the bending of the perpendicular plates, thus protecting the welds. You DO NOT want to use a cam bolt to repeatedly clamp (bend the bracket) and release. This WILL cause fatigue and weld failure which makes you a hazard to everyone behind you.

The OP needs to smarten up and follow the good advice already given or find the log out button and never look back.

Now for the negative:

View attachment 217201

D Days - I hope it's ok that I borrowed your picture.