JamesNZ

New member

This build has been I guess in the process for a couple years now, the mods I'm sharing today started 12 months ago from the moment it was put on the trailer.

A little about myself: My name is James as you may have captured already, I'm from Christchurch, New Zealand. This XJ is my first Jeep purchased coming up to 5 years ago now, haven't wheeled it much as it's spent most its time undergoing modifications. Before this vehicle most of my 4WD adventures were in a 70 Series Land Cruiser and a GQ Nissan Safari/Patrol.

Little old New Zealand doesn't have much places for the extensive modifications and fabrication work I desired on my Jeep. Luckily there was one local that stood out from our small community who has a passion for offroad and happens to enjoy the type of wheelin' I do and fabricate his own designs like nothing I've ever seen before. So an honorable mention to Tom's Offroad and Customs, all the fabrication work and photo work seen below is courtesy of Tom himself.

Now to the build that has mostly been inspired around rock crawling;

Goal is to squeeze 14" coilovers front and rear, re-do the front bar to more of a stubby front bumper which will support the front fenders etc. and the external cage will tie into everything (effectively trying to make a road legal buggy). The involvement of doing these goals, well the photos below speak for themselves!

I am a little concerned about weight, I'm expecting this to weigh under 2.4 tonne, but really unknown where she will be sitting now starting from 1.8 Tonne!

Following all the beautiful fabrication work from Tom (Tom's Offroad and Customs) I'll be stripping her right back, engine trans and all to carry out an extensive paint job to the undercarriage, interior and exterior. Then i'll be piecing her back together again.

Hopefully later down the track when the pockets aren't so empty I can revisit the running gear.

I'm just really looking forward to getting her back on the road again to start wheelin' again.

1. Loaded up ready to go extensive modifications, this was when it was sitting on 33 inch tyres and an IRO Long Arm Kit, I'd also just freshly done some sanding and primer work on her as will be changing the colour down the track (the burgundy colour wasn't doing it for me).

2. The first mission was installing the mid frame stiffeners from Iron Rock Offroad, after hearing all of those stories about the doors falling off XJ's it seemed like a logical thing to do first :lol:, by the way these frame stiffeners are a great fit.

3. Next was to help with clearance, so trimming and replacing the sills gave the clearance and additional protection. Although this doesn't solve the transmission vulnerability it should help navigate rocks a little easier!

4. Some added bracing or stiffening to the sills.

5. Next a rear quarter chop just seemed logical, this build was and still is growing rapidly.

6. The dual triangulated 4 link was ready to begin, having the beefed frame gave something for us to work with and come up with a new rear cross member that was to link the arms.

Tacked IRO truss.

Tacked rear cross member.

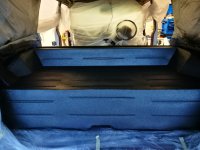

7. Cutting the floor up was one small sacrifice required for the dual triangulated 4 link to work, the factory floor was too restrictive for it too work efficiently (or at all).

A little about myself: My name is James as you may have captured already, I'm from Christchurch, New Zealand. This XJ is my first Jeep purchased coming up to 5 years ago now, haven't wheeled it much as it's spent most its time undergoing modifications. Before this vehicle most of my 4WD adventures were in a 70 Series Land Cruiser and a GQ Nissan Safari/Patrol.

Little old New Zealand doesn't have much places for the extensive modifications and fabrication work I desired on my Jeep. Luckily there was one local that stood out from our small community who has a passion for offroad and happens to enjoy the type of wheelin' I do and fabricate his own designs like nothing I've ever seen before. So an honorable mention to Tom's Offroad and Customs, all the fabrication work and photo work seen below is courtesy of Tom himself.

Now to the build that has mostly been inspired around rock crawling;

Goal is to squeeze 14" coilovers front and rear, re-do the front bar to more of a stubby front bumper which will support the front fenders etc. and the external cage will tie into everything (effectively trying to make a road legal buggy). The involvement of doing these goals, well the photos below speak for themselves!

I am a little concerned about weight, I'm expecting this to weigh under 2.4 tonne, but really unknown where she will be sitting now starting from 1.8 Tonne!

Following all the beautiful fabrication work from Tom (Tom's Offroad and Customs) I'll be stripping her right back, engine trans and all to carry out an extensive paint job to the undercarriage, interior and exterior. Then i'll be piecing her back together again.

Hopefully later down the track when the pockets aren't so empty I can revisit the running gear.

I'm just really looking forward to getting her back on the road again to start wheelin' again.

1. Loaded up ready to go extensive modifications, this was when it was sitting on 33 inch tyres and an IRO Long Arm Kit, I'd also just freshly done some sanding and primer work on her as will be changing the colour down the track (the burgundy colour wasn't doing it for me).

2. The first mission was installing the mid frame stiffeners from Iron Rock Offroad, after hearing all of those stories about the doors falling off XJ's it seemed like a logical thing to do first :lol:, by the way these frame stiffeners are a great fit.

3. Next was to help with clearance, so trimming and replacing the sills gave the clearance and additional protection. Although this doesn't solve the transmission vulnerability it should help navigate rocks a little easier!

4. Some added bracing or stiffening to the sills.

5. Next a rear quarter chop just seemed logical, this build was and still is growing rapidly.

6. The dual triangulated 4 link was ready to begin, having the beefed frame gave something for us to work with and come up with a new rear cross member that was to link the arms.

Tacked IRO truss.

Tacked rear cross member.

7. Cutting the floor up was one small sacrifice required for the dual triangulated 4 link to work, the factory floor was too restrictive for it too work efficiently (or at all).

Last edited: