There are a few kits out there that simply move the stock caliper out further with a new saddle and adapter bracket. In the testing we've done on the same vehicle with no other changes, the relocation of the stock caliper and 1" larger rotor proved more effective in all regards than the kit you referenced.

With prior vehicles that I've upgraded brake systems on, I've noticed the same. The bigger the rotor, the more obvious the braking improvement. Even if keeping every other component the same. Thus why I'm really pushing with trying to make this 14" (actually like 14.2") rotor work. I'm kinda at a tough point right now though, debating the caliper. In theory, that nice shiny red 4-piston caliper I'm experimenting with has less piston surface area

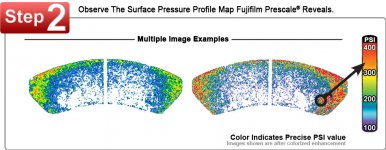

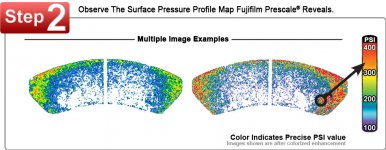

equivalent than any of several more common 2 piston floating calipers I could choose from, but it MIGHT make up for alot of that piston area loss because of its more rigid design and better distribution of "squeeze". It also should, in theory, have the benefit of better heat dissipation. Like I mentioned earlier, it's just hard to come to an answer of which is a stronger brake without springing cash for 4 4-piston calipers and matching rotors, and ANOTHER set of 4 2-piston calipers and matching rotors and then doing back to back comparisons.

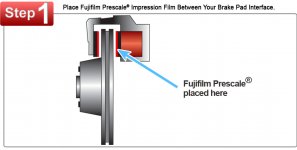

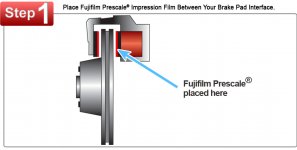

I was hoping maybe the pressure film might help me avoid that big expense and give me good, hard data that wasn't just a "oh, system A feels stronger than system B".

One of the things that keeps me pursuing these 4-piston calipers, though, is that because of the effective piston surface area being smaller than other possible caliper choices, it should enable the use of either the stock or an only slightly larger bore 1 1/16" master cylinder. (Honestly, stock is likely to work great with these.)

I know there are systems out there that can be purchased right off the shelf that offer jeepers better brakes, and I'm appreciative of those vendors' solutions! I guess I'm just having fun trying to be the regular joe seeing if he can build a WOW brake system on his own, and using off the shelf stuff!! :yup: