wwood

Member

While I would have agreed that 5° of positive caster was a good thing 6 years ago, I would not recommend you do that now. Depending on what gear ratio you are running, this will cause driveline vibrations and over time, will lead to transfer case housing failure. How do I know, it's happened to me and I have personally seen it happen on 2 other JK's. Since then, I would only recommend that you restore your caster back to stock which is about 4°.

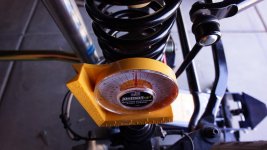

Having said that, you cannot just set your lowers and upper arms to fixed lengths and expect your caster to be some exact angle. To suggest that is just stupid. If that were true, you could install any lift you want with stock arms and nothing would change and that's just not the case. The amount of lift you actually have changes the angle you need/want and that's why adjustable control arms are nice to have - so that you can make changes to the angle. If you have both upper and lower adjustable arms, you'll want to use your lower arms to set your axle position and your upper arms to set your caster. I do use 23" as a starting point but, depending on how much lift you actually have, I often find that they need to be set them a bit shorter. With the upper arms disconnected from the axle mounts, use a floor jack to raise or lower your axle angle from the pinion until you have the caster you need. One of the easiest ways to do this is to take an angle finder and place it over the flat spot on the front of your differential where you would normally attach a case spreader as shown below...

[image snipped]

When you have a reading of 0° here, you will have 4° of caster. Set your control upper control arms so that you can get one installed on the axle, measure it's length and then set the opposite side arm according. Getting the second arm installed can be tough and using your floor jack to raise or lower your pinion will help to make this possible.

Thanks Eddie, I really appreciate this info. I am installing a full set of adjustable arms with 3" EVO plush coils this coming week and your tips will save me a lot of guessing.