ERAUGrad04

Caught the Bug

Today I tackled the fit of the new Slab on the AEV Tire Carrier. With the Fuel Caddy, the closest I could get the tire to the carrier tubing was about 1". While the flange is able to hold the weight of the tire/wheel assembly, the tire not being sucked up to the tire carrier tubing would lead to vibration, extra stress and fatigue on the flange. I figure over a long period of time, this could result in a failure of the flange assembly that the tire is bolted to.

As luck would have it, I happened to have two extra bumpstops in the garage. When I made the jump to 37s, I had to replace the rear bumpstops and the kit came with new front bumpstops as well even though I did not need them.

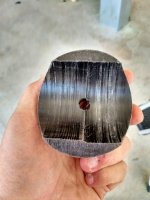

I picked up a 2-1/4" hole saw and went to work on the drill press.

The thickness of the spacer is a total of 1-1/4" which will take up the 1" gap and an additional 1/4" for the tire to snug up to. I used stainless hardware to attach the newly created pucks to the tire carrier frame.

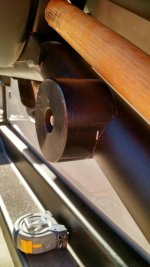

I made three pucks in total and here is the tire all snugged up to the frame:

Thanks for looking!

As luck would have it, I happened to have two extra bumpstops in the garage. When I made the jump to 37s, I had to replace the rear bumpstops and the kit came with new front bumpstops as well even though I did not need them.

I picked up a 2-1/4" hole saw and went to work on the drill press.

The thickness of the spacer is a total of 1-1/4" which will take up the 1" gap and an additional 1/4" for the tire to snug up to. I used stainless hardware to attach the newly created pucks to the tire carrier frame.

I made three pucks in total and here is the tire all snugged up to the frame:

Thanks for looking!