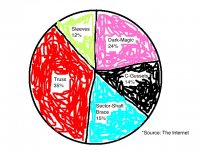

Nothing will stop your axle from bending however thick the wall is, its just whether the loading takes it over the elastic limit. But a 2.5" x 0.25" thk tube will bend more than a 2.5" x 0.25" thk tube with a 0.25" thk inner sleeve.

View attachment 103417

2.5" x 0.25" thk x 36" lg tube with 2500lbs on one end will bend 1.2"

View attachment 103418

2.5" x 0.25" thk x 36" lg tube/ 0.25" inner sleeve with 2500lbs on one end will bend 0.8"

Mel at ORE seems to understand the physics and an axle tube will be 30% strong with a sleeve. Maybe you can get him to explain it to you one day.

A sector shaft brace is only $100. Maybe you should have both, you know that you will help somebody else and then yours will go on the next obstacle.

At least you wrote something this time (however wrong it maybe) and not just reply

bullshit