So you pull up to a big obstacle all ready to take it on, you turn on your ARB compressor, turn on your front and rear lockers, attempt to start climbing it... struggle... and then your spotter yells out, "YOU'RE LOCKERS AREN'T ON!" Or, you turn on your lockers and all you hear is your compressor buzzing away while pumping a whole lot of air into thin air. A common scenario that every ARB locker owner has experienced at least once and it's a reason why some steer clear of them and that's a shame being that when they work, ARB's work well and are really strong.

The biggest problem with the blue plastic ARB air line that comes standard with their lockers is that most people route them too close to the exhaust or other engine component that gets really hot and that causes it to melt. Or, they run it next to something sharp and movement allows it to chafe and get cut. Then, there are some who run the line through the frame rail thinking that would protect it but of course, the exhaust runs right along side it and it can get hot enough to melt the line as well. With a severed line, your compressor will just keep on running and that makes it easy to figure out what's going on. Of course, more times than not, the line will just melt causing the line to pinch off and when this happens, your compressor will still come on, charge up the length of line leading out of it and give you the false impression that your lockers are engaged. This is always the worst being that it can be difficult to track down a melted line especially if it's run though the frame rail.

The solution, or at least what I have found, is to install a set of stainless steel air lines. They aren't cheap but ever since I started running them, I always have lockers and I have yet to have a problem with them. They are durable, resist chaffing, difficult to cut and can handle a greater amount of heat. Naysayers will tell you that the standard blue plastic ARB air line is easy to repair but to that, all I can say is that I have yet to have a stainless steel line fail on me.

For the purposes of this write-up I am using a set of Russell stainless steel lines although, I have used Rubicon Express in the past and of course, ARB makes a set too.

What you will need

• Russell 634520 Rear Air Line Kit

• Russell 634510 Front Air Line Kit

• Russell Universal Braided Stainless Steel Brake Line - 32" (as needed)

• 3/8" x 24 UNF Stainless Steel Adapter (only if extension is needed)

• (2) 11mm wrenches

• 13mm Wrench

• 5/16" Wrench

• 9/16" Wrench

• Zip Ties

Here's a shot of the front and rear air lines as well as an additional 32" extension that I needed for Rubicat and her rear ProRock 60.

This is the 32" extension as well as the 3/8" x 24 UNF Stainless Steel Adapter that is needed to make it work.

Instructions

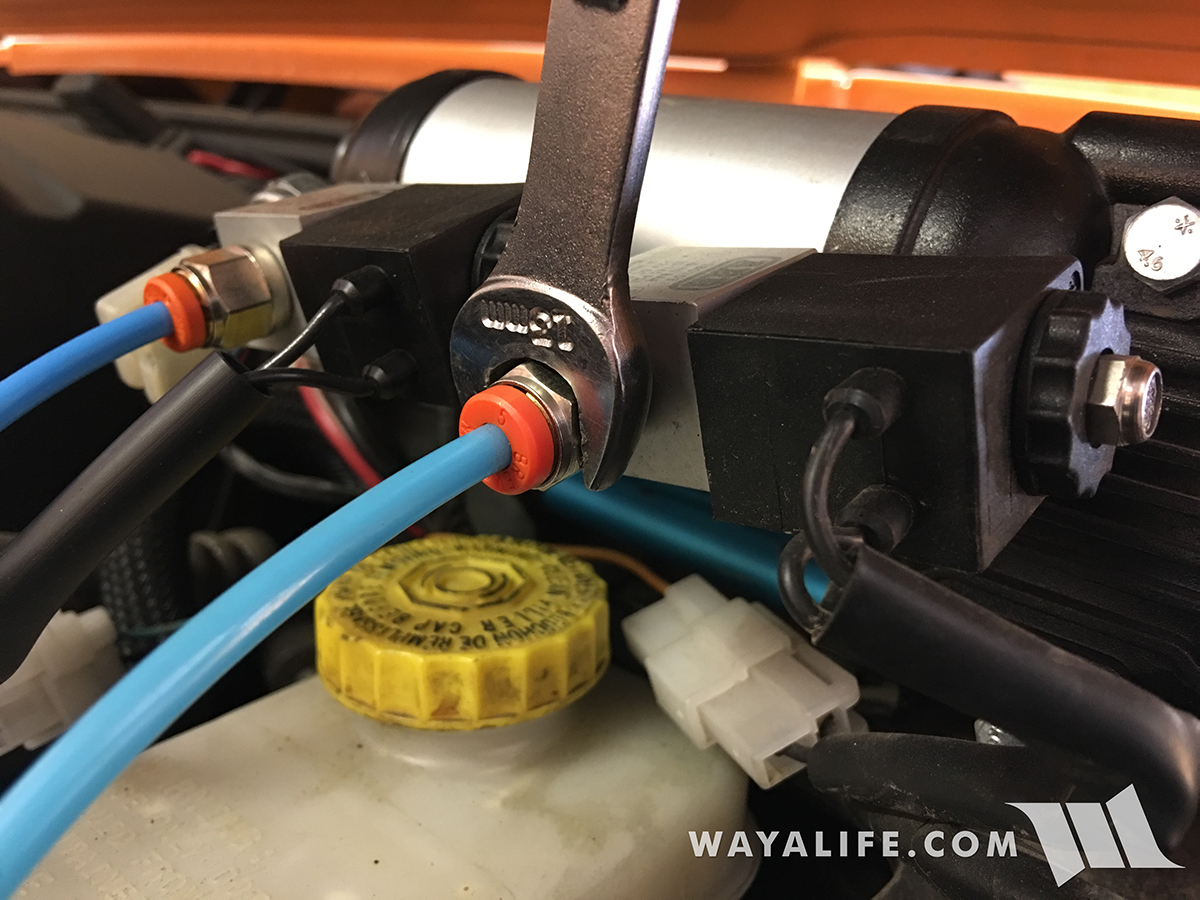

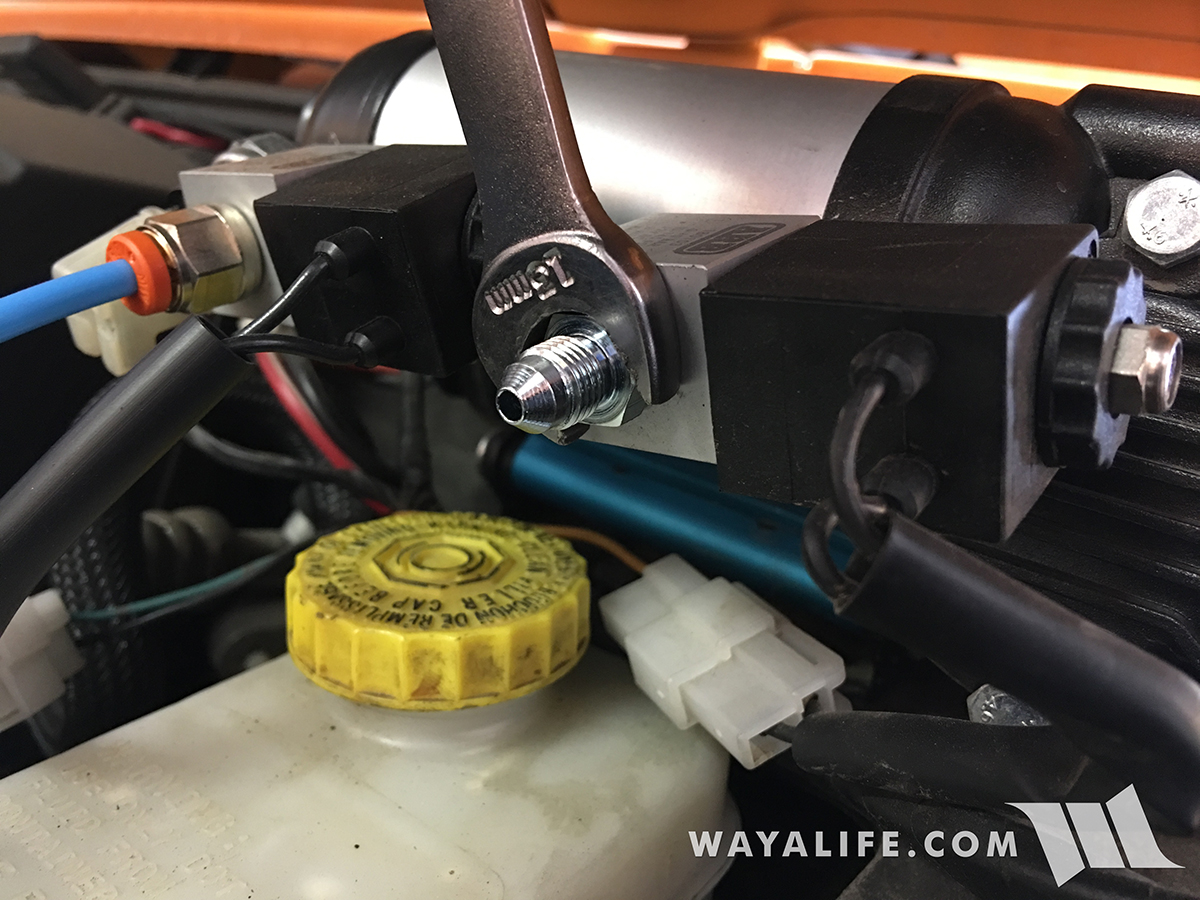

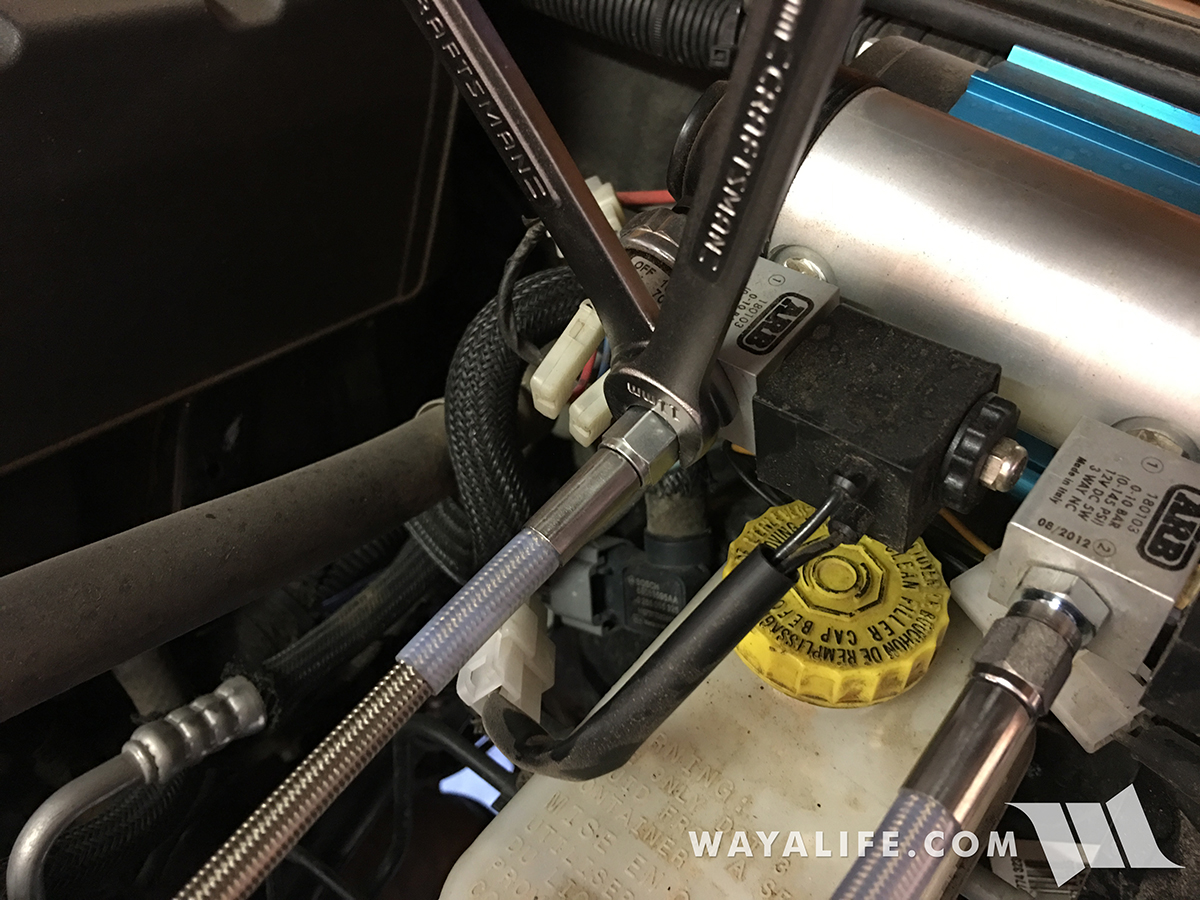

1. Begin the installation of your new stainless steel air lines by removing the blue plastic ARB ones attached to your compressor. You will need a 13mm wrench to separate the fitting from the solenoid.

2. Using a 13mm wrench, secure the new solenoid fitting that comes with your your stainless steel air line kit.

3. Using a 13mm wrench to hold the solenoid fitting in place, secure the rear stainless steel air line to the fitting using an 11mm wrench.

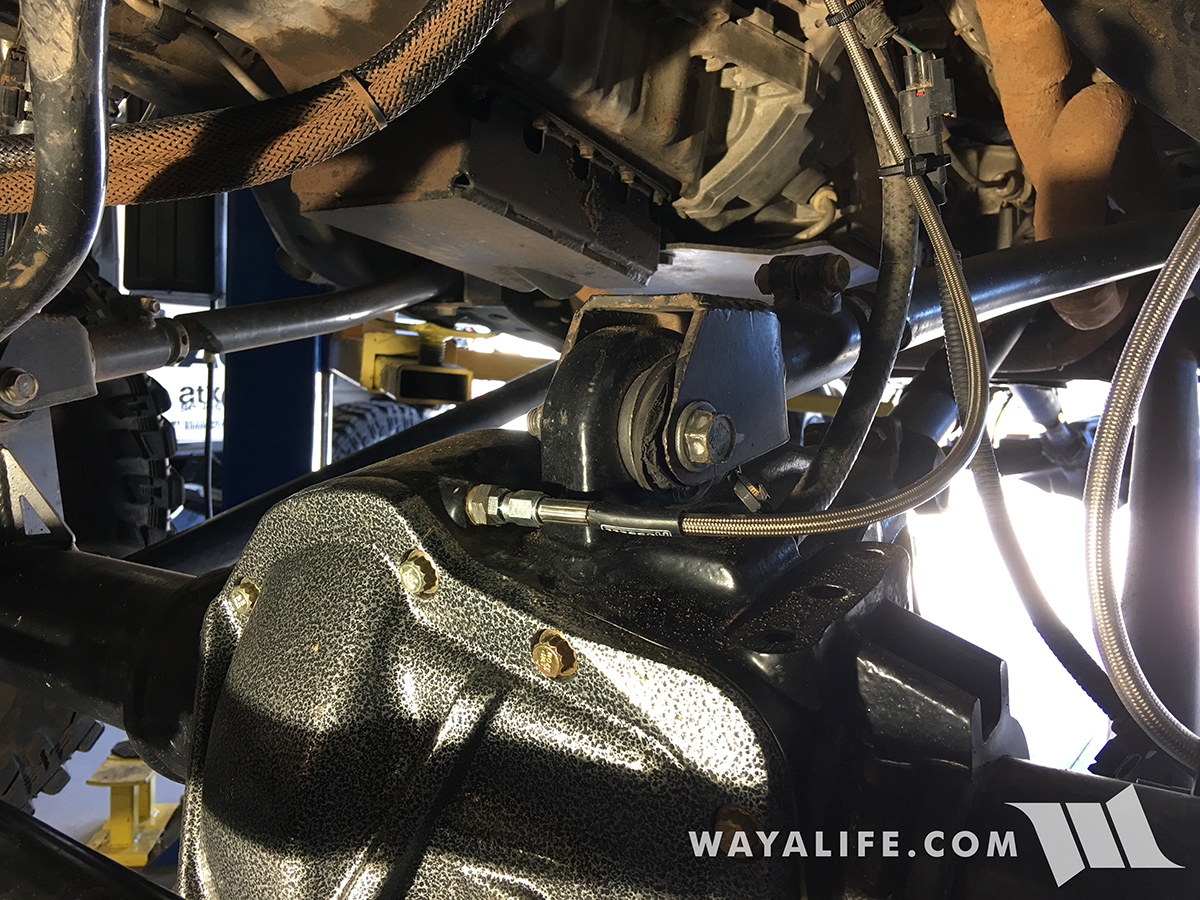

4. Route your stainless steel air line to the back of your Jeep. I prefer to do this on the outside of the frame rail and along side the body mounts.

5. Because of the location of the ARB bulkhead fitting on our Dynatrac rear ProRock 60 axle and the amount of droop we get with our EVO Lever, an additional amount of air line was needed. To make this work, I had to install a 3/8" x 24 UNF Stainless Steel Adapter. If you are not in need of an extension, proceed to step #7.

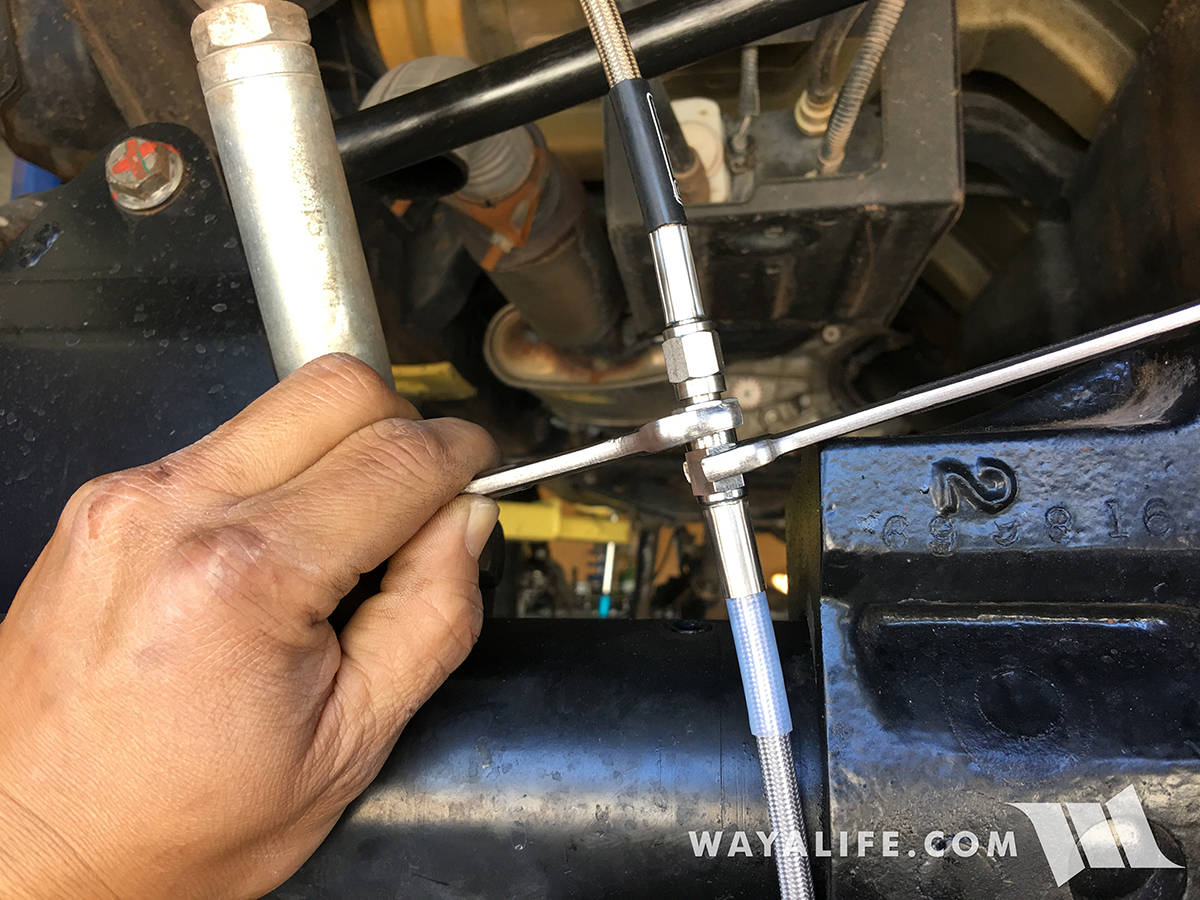

You will need an 11mm and a 13mm wrench to secure the adapter to the stainless steel air line.

6. Attach the 32" stainless steel extension to the adapter and secure it in place using a 13mm and 11mm wrench.

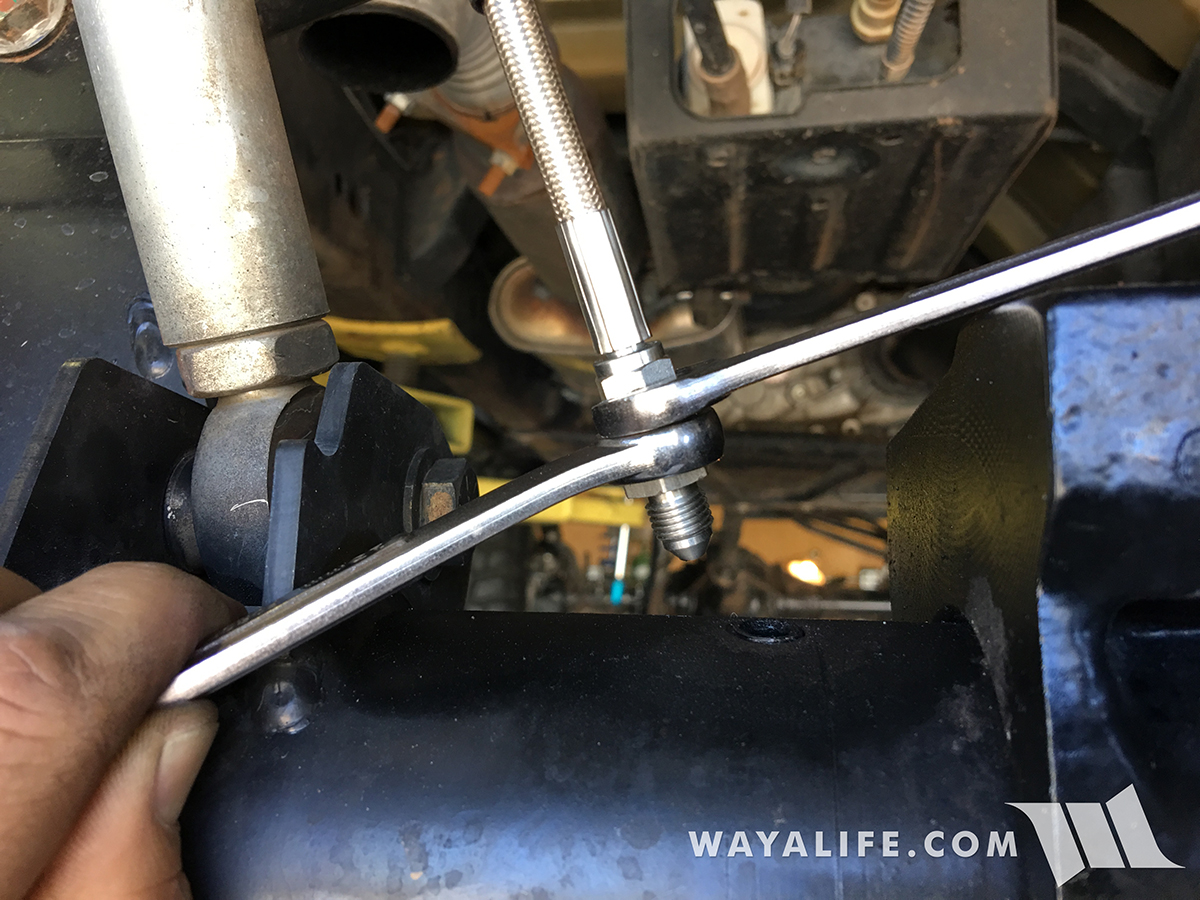

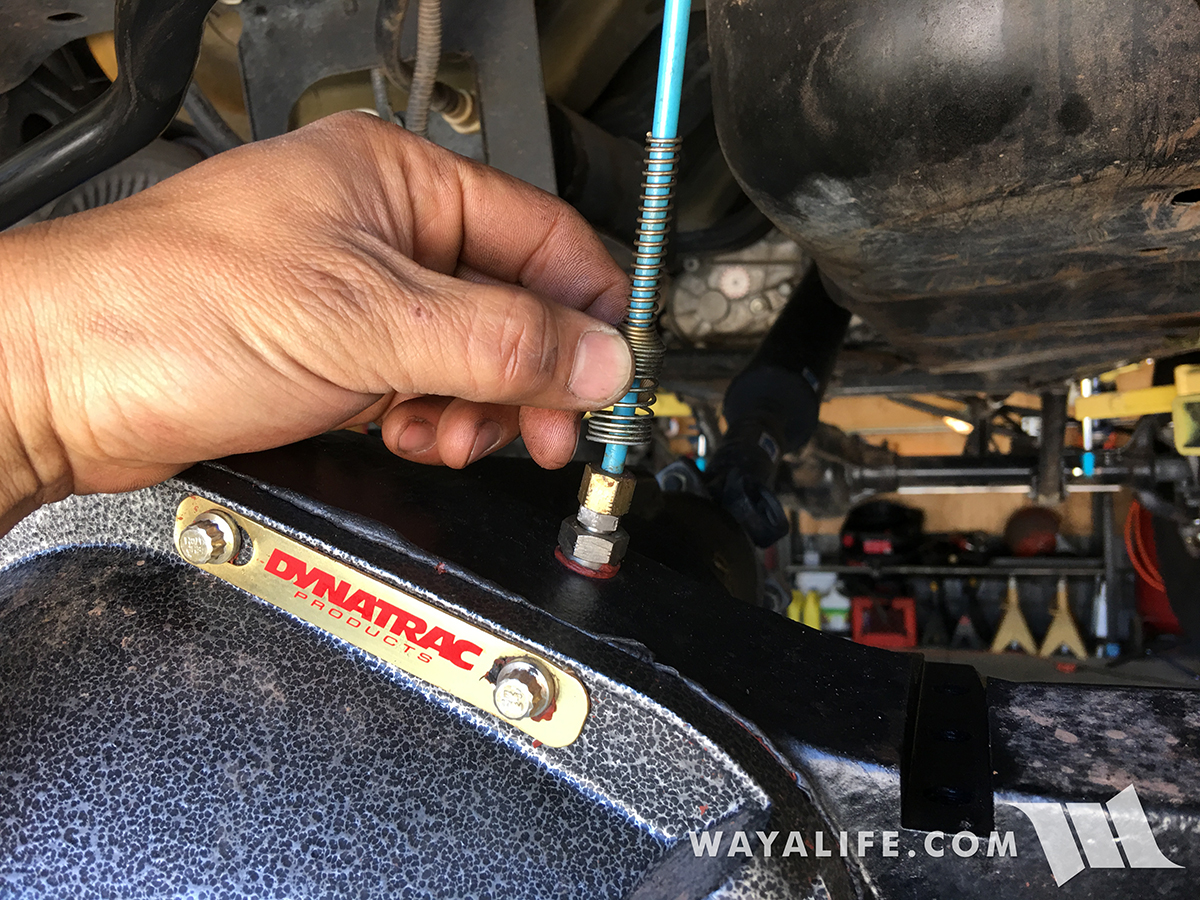

7. Pull the spring up and off the brass bulk head fitting attached to your axle.

8. Hold the bulkhead fitting with a 9/16" wrench and then remove the blue plastic air line fitting using a 5/16" wrench.

9. Continue holding the bulkhead fitting with a 9/16" wrench and then secure the new stainless steel air line fitting on to it using an 11mm wrench.

10. Use one 11mm wrench to hold the fitting attached to the bulkhead and use another 11mm wrench to secure the stainless steel air line to it.

11. Zip tie your stainless steel air line to your body mounts or other fixtures and you're done.

12. Repeat the same process for your front axle.

That's all there is to it. Check for leaks and you're done. Please let me know if you have any questions.