You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not too proud to admit I can’t do something.

- Thread starter notnalc68

- Start date

TrailHunter

Hooked

^^^ that’s pretty damn cool right there. [emoji1360]

fiend

Caught the Bug

I don’t really like the design either but they guarantee those bolts will hold up to the rocks.l like the look of those wheels as well. I live in Midwest, I get a chance to come out and play maybe 3-4 times a year. I do play in the rocks when I have a chance to visit the closest off-road Park thats 2 hours away. I’ve been running my non beadlocks wheels at 12psi when crawling without too much struggle. After this whole thing I wonder if I even the beadlock wheels. The Jeep isn’t driven daily too much though, my wife drives it to school, back and around town, maybe 10-20 miles a day tops. Occasional trips on the weekends. Am puzzled...

Well, I guess just leave it be.

Ok well you know your needs better than I do. If, as appears, those wheels have a steel bolt threading into aluminum threads, that’s another reason to get rid of them IMO. They should be using steel inserts. Any way, good luck![emoji256][emoji1360]

VeruGE*144

Caught the Bug

Ok well you know your needs better than I do. If, as appears, those wheels have a steel bolt threading into aluminum threads, that’s another reason to get rid of them IMO. They should be using steel inserts. Any way, good luck![emoji256][emoji1360]

You’re right. Those wheels are complete shit! I tried another one with their bolts and I maybe barely got another turn out of them before the bolt holes started stripping out. I am fucking furious right now. I am so done with them. I guess a bolt is a bolt and the aluminum wheel without steel inserts is the problem.

Last edited:

sipafz

Caught the Bug

I did a spacer lift on my buddies RAM 1500 with IFS. Rear was simple, solid axle just put the spacer in between the spring and the frame. For his front we replaced the shock. The height was set with a little circlip,

View attachment 303040

same spring was reused and strut went back in without any problems. His did not have the sway bar link attached to it though. The install of the front wasn’t so bad except that we were using autozone spring compressors and had to cut of the little nut on top the shock to take the whole assembly apart. Took like an hour to cut of each nut.

I feel your pain, things aren’t always working the way we would like them to. I respect the fact you can admit the defeat.

Well fuck, since you started this thread, please allow me to vent some of my frustration in here.

Long story short I got all 5 AEV wheels replaced under warranty free of charge, and was offered to pick form any wheels I wanted. I decided to go with their new beadlocks. Got the wheels, they came with galvanized metric bolts. I really wanted to have black bolts on my beadlock rings. Spent few days looking for bolts in phosphate finish. It’s really fucking hard to find metric bolts. I wanted to go with 12points or button heads, couldn’t find shit in the grade I needed. Spent few more days researching grading and blot class. Eventually I settled on same type of bolt (flange bolt) within the same class 10.9. Ordered the bolts, after they came in, the threads weren’t quite as long as I needed them to be.

View attachment 303043

View attachment 303044

I decided to extend the threads with my little tapping jig. Spent couple hours doing so and did about 50 out of 120

View attachment 303045

View attachment 303046

View attachment 303047

This past Saturday I tried mounting my spare tire. About 8 to 10 bolt holes started stripping before I even got close to closing the gap between the ring and the wheel. Some bolts literally fucking poped out, pulling the threads out with them.

View attachment 303048

View attachment 303049

View attachment 303050

I abandoned the project, fought to pull the fucking rim back out of the tire. I did more research on bolts and extending the threads and shit. I found that I am using full body bolts. When those are extruded, a little angle at the end of the threads if left of.

View attachment 303051

If you try to extend the threads over that angle you end up with two or three incomplete threads.

View attachment 303052

Not sure if this I what caused the bolts hole to strip because they were stripping way before that area of the bolt was threaded in.

I am getting another wheel sent over from AEV. But what do I do now? Did I make a mistake or was is just defective wheel? Are those wheels just shit and the next one will strip them same way? Do I swallow my pride and just use their bolts, are they special in some way? But I don’t want the galvanized bolts, I want the fucking black phosphate bolts. Do I just sell those wheels and go with something else? I like those fucking wheels though. I can’t find the correct length bolts. Custom made bolts can only be made with a minimum of 2500 pieces, which is a little more than I need.

I am so fucking frustrated. I have done enough research on bolt class and manufacturing processes that I’ll be a writing fucking a book on bolts soon. I am absolutely dumbfounded. Fuck me, I just spent 30 minutes writing this post..... not sure If I feel any better about myself right now.

cheers mate, [emoji482]

Tough lesson for sure! Bolt threads are rolled and a rolled thread major diameter is quite different than a cut thread major diameter. You have a good picture in your post of a bolt blank prior to rolling the thread, showing the major diameter for rolling and the full body diameter. Your also absolutely right out the “half threads” leading into the chamfer. I’m not sure if that caused the damage, but another thing to consider is that the full body area where you added threads might be slightly larger than the maximum major diameter for a cut thread. If that’s the case the thread crest will bottom out into the mating thread root, causing damage.

That aside, find an industrial platter locally that does phosphorus oxide. They can strip the zinc off and re-plate the OEM bolts.

Now I realize that I was responding to an older post you can totally disregard mine. Sorry to hear about your troubles!

Last edited:

VeruGE*144

Caught the Bug

Tough lesson for sure! Bolt threads are rolled and a rolled thread major diameter is quite different than a cut thread major diameter. You have a good picture in your post of a bolt blank prior to rolling the thread, showing the major diameter for rolling and the full body diameter. Your also absolutely right out the “half threads” leading into the chamfer. I’m not sure if that caused the damage, but another thing to consider is that the full body area where you added threads might be slightly larger than the maximum major diameter for a cut thread. If that’s the case the thread crest will bottom out into the mating thread root, causing damage.

That aside, find an industrial platter locally that does phosphorus oxide. They can strip the zinc off and re-plate the OEM bolts.

Now I realize that I was responding to an older post you can totally disregard mine. Sorry to hear about your troubles!

Yea, I agree that I messed up with the bolts, but their bolts did the same thing.

notnalc68

That dude from Mississippi

Yea, I agree that I messed up with the bolts, but their bolts did the same thing.

That blows. Glad they replaced it, but those are expensive wheels for something like that to happen.

Sent from my iPhone using WAYALIFE mobile app

Overland_stormtrooper

Caught the Bug

sipafz

Caught the Bug

Yea, I agree that I messed up with the bolts, but their bolts did the same thing.

Weird for sure! I agree with Fiend that the wheels should have helicoils. If you really love the wheels you could maybe add them? It would be expensive and time consuming probably making it not worth it.

I’m sure you’re following the instructions for tightening the ring. It must be something like a little at a time around the ring or a cross over pattern or something? Not just cranking each down to spec right away.

Last edited:

VeruGE*144

Caught the Bug

Weird for sure! I agree with Fiend that the wheels should have helicoils. If you really love the wheels you could maybe add them? It would be expensive and time consuming probably making it not worth it.

I’m sure you’re following the instructions for tightening the ring. It must be something like a little at a time around the ring or a cross over pattern or something? Not just cranking each down to spec right away.

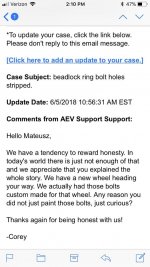

For anybody that might have missed what I said in my previous couple posts. I did paint their bolts and tried again with a new wheel they sent me.

I always OCD about torquing everything to spec with anything I do. I was extra careful, I even used an in/lbs torque wrench on the first two steps of their torquing instructions(I don’t think a ft/lbs torque wrench is accurate under 20 ft/lbs). I literally sung them fucking things down half a turn each before even starting with a torque wrench. Also applied antisieze per instructions. I don’t think anybody on this planet could be more gentle with doing this.

Guess what all the blue tape means. About 5-8 bolt holes stripped out using their bolts before I even got to 16ft/lbs, which is their second step of torquing those shitty wheels down. Again pulling the fucking threads right out the bolt holes. With still a 1/4” of space between the ring and the wheel. They pretty much stripped out at the same spot that my bolts did.

The thickness of the bead on my KM2s is about 13/16” to 7/8”.

I did get the wheels replaced free under warranty when my old pintler wheel carcked at the spoke, but I had to pay extra for the beadlock rings. So now $700 later I am stuck with a set of 6 shitty wheels. I really hope I can get my money back for whatever I paid, send that crap back and get a set of fresh pintlers instead. Sell the Pintlers and get a set of some real beadlock wheels. I am just fucking furious right now. I am done with those wheels, I don’t want them anymore and I don’t want anything to do with AEV anymore. I wouldn’t even feel comfortable selling those to anyone.

Last edited:

sipafz

Caught the Bug

For anybody that might have missed what I said in my previous couple posts. I did paint their bolts and tried again with a new wheel they sent me.

View attachment 303351

View attachment 303352

I always OCD about torquing everything to spec with anything I do. I was extra careful, I even used an in/lbs torque wrench on the first two steps of their torquing instructions(I don’t think a ft/lbs torque wrench is accurate under 20 ft/lbs). I literally sung them fucking things down half a turn each before even starting with a torque wrench. Also applied antisieze per instructions. I don’t think anybody on this planet could be more gentle with doing this.

View attachment 303353

View attachment 303354

Guess what all the blue tape means. About 5-8 bolt holes stripped out using their bolts before I even got to 16ft/lbs, which is their second step of torquing those shitty wheels down. Again pulling the fucking threads right out the bolt holes. With still a 1/4” of space between the ring and the wheel. They pretty much stripped out at the same spot that my bolts did.

View attachment 303355

View attachment 303356

View attachment 303357

The thickness of the bead on my KM2s is about 13/16” to 7/8”.

View attachment 303358

I did get the wheels replaced free under warranty when my old pintler wheel carcked at the spoke, but I had to pay extra for the beadlock rings. So now $700 later I am stuck with a set of 6 shitty wheels. I really hope I can get my money back for whatever I paid, send that crap back and get a set of fresh pintlers instead. Sell the Pintlers and get a set of some real beadlock wheels. I am just fucking furious right now. I am done with those wheels, I don’t want them anymore and I don’t want anything to do with AEV anymore. I wouldn’t even feel comfortable selling those to anyone.

Unbelievable! I can’t even imagine your frustration with this. Shitty wheels for sure! I hope you’re able to get this worked out.

WJCO

Meme King

For anybody that might have missed what I said in my ....

I did get the wheels replaced free under warranty when my old pintler wheel carcked at the spoke, but I had to pay extra for the beadlock rings. So now $700 later I am stuck with a set of 6 shitty wheels. I really hope I can get my money back for whatever I paid, send that crap back and get a set of fresh pintlers instead. Sell the Pintlers and get a set of some real beadlock wheels. I am just fucking furious right now. I am done with those wheels, I don’t want them anymore and I don’t want anything to do with AEV anymore. I wouldn’t even feel comfortable selling those to anyone.

Really sorry to hear this. Seems like you're doing everything right. What a pain in the ass.

VeruGE*144

Caught the Bug

Really sorry to hear this. Seems like you're doing everything right. What a pain in the ass.

I don’t think I am even mad anymore, just really disappointed. I did not expect to have to deal with such nonsense, especially with company like them. Oh well, I will never buy anything form the ever again. Just really hope I can get my money back I paid for the rings and move on to real wheels.

piginajeep

The Original Smartass

I don’t want to commit to reading this entire thread.

But hasn’t anyone called you a pussy yet?

But hasn’t anyone called you a pussy yet?

VeruGE*144

Caught the Bug

I don’t want to commit to reading this entire thread.

But hasn’t anyone called you a pussy yet?

No, nobody called me that yet lol. I didn’t even start this thread, I somehow ended up hijacking it.....

piginajeep

The Original Smartass

No, nobody called me that yet lol. I didn’t even start this thread, I somehow ended up hijacking it.....*

I was talking to the OP, but

notnalc68

That dude from Mississippi

I don’t want to commit to reading this entire thread.

But hasn’t anyone called you a pussy yet?

Yeah, Catahoula did. I think it’s because the struts are made differently, than earlier models.

Sent from my iPhone using WAYALIFE mobile app

TrailHunter

Hooked

Yeah, Catahoula did. I think it’s because the struts are made differently, than earlier models.

Sent from my iPhone using WAYALIFE mobile app

Did you ever contact the Manufacturer? Or still just Fuck it? [emoji51]

notnalc68

That dude from Mississippi

Did you ever contact the Manufacturer? Or still just Fuck it? [emoji51]

I haven’t got around to it. I’m going to see if I can get a refund.

Sent from my iPhone using WAYALIFE mobile app