MTG

Caught the Bug

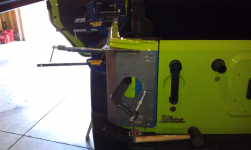

Prime8 said:Another road block... This 1/4 Pounder install is a nightmare...

In order to be ready for full install once the vacuum relocation kit arrives, I decided to go out and get the sway bar disconnect motor relocated. Taped up my bit at 1/2" just like the directions said, and bored out the hole. Tried to thread in the bolt and it wouldn't grip the ~0.5mm left I'm the hole. So I trimmed it a little more. Still wouldn't grip. The third time it ate right through and bored the hole out completely. So now what...? Had to put the motor back in its original location since it wouldn't have held without any threading...

This install is quickly becoming a huge hassle, I hope the rear carrier doesn't have as many hiccups.

<img src="http://wayalife.com/attachment.php?attachmentid=6841"/>

<img src="http://wayalife.com/attachment.php?attachmentid=6840"/>

I'm not in front of my jeep but from memory that doesn't look like the spot I drilled. Can you take a pic a little further away?