Jane’s Carburetor CALAMITY

Being that Cindy and I were so focused on stripping Jane down, cleaning her up and getting ready for paint, addressing one of her biggest calamities – getting her started and running well was always something that we put on the back burner or at least, up until now. Being that her day at paint is just around the corner, I decided that it was finally time to address this problem and as I would come to find, it was something that I NEEDED to address.

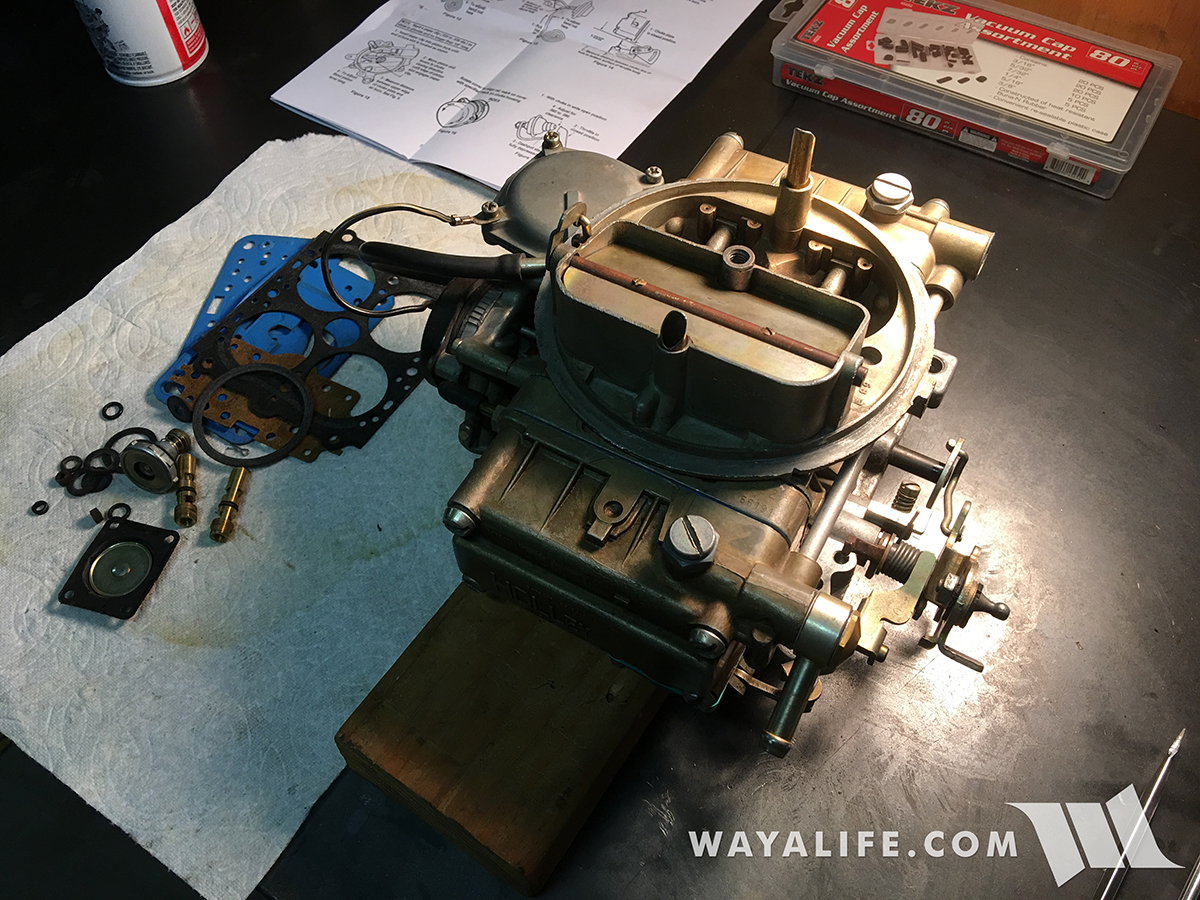

If there’s one thing I hate most about buying a used Jeep, it’s that they always comes with baggage – the mistakes left behind from the previous owner. For better or for worse, Jane had her intake manifold changed to a square bore, 4-barrel setup and had a Holley 4160 installed on top of it. Pulling in 600 cfm, it was definitely on the big side for an AMC 304 and was probably a better fit for something like an 360 or 401 and if I could guess, some of the problems we were having may have been related to that. That being said, I don’t think the patch work of homemade vacuum plugs or the hose coming out of the PCV valve going nowhere or the fuel filter that was installed backwards was helping anything. In fact, the more I took things apart, the more I started to wonder how Jane was able to run at all. But, after a quick trip to my local Summit Racing store, I was well on my way to tearing Jane’s carb down and rebuilding it.

Thoroughly cleaned and with all new needles, valves and gaskets installed, I double checked my work, reinstalled the carb and then tried firing her up. And, I say “tried” because trying was about all I could do. In spite of all my efforts, the most I could get was her engine fired up and running for just a bit before it would abruptly quit and when did, it’d let out a big sneeze out the carb. And – that’s about when I ran into a new problem. Assuming she was flooded, I let her rest for a bit, vented her carb and when I went to try it again – I got nothing. I mean, absolutely nothing happened – not a click, not a buzz, not a cough, not a sound – just silence. Being that an old Jeep like this doesn’t have any fuses, I proceed to look for any loose wires and checked all the connections I could but found nothing. Stumped, I decided to just try the key again and much to my surprise, it started cranking again. However, after a handful of “almost starts” – I got nothing again. And, that’s when I decided to make a run down to my local Autozone and pick up a new ignition coil. Among other things, a failing ignition coil would result in things like backfire, misfire, poor fuel economy and fouled plugs but the most common symptom you’d see is an engine that runs for a bit and then just quits. With a new ignition coil installed, Jane was cranking again, consistently and I was finally able to get back to looking for my original problem – getting her to run!

With Jane’s electrical problem fixed, I could only assume she was having some kind of fuel delivery problem and so along with a new fuel filter (installed the right way), I also installed a new fuel pump but unfortunately, they fixed nothing. When I turned the key, she would fire up, run for just a bit and just as I would get out to give things a closer look – her engine would die and with a big sneeze.

Assuming she was flooding, I did a check of the float levels and even tried lowering them a bit but still got the same results. Just to make sure, I made sure to set the idle mixture adjustment screws to the default starting position as stated in the manual but still got the same thing happening. Thinking that maybe she was having a timing issues, I did a manual check to verify that she was hitting TDC on the proper stroke and made sure that her vacuum advance was working. Questioning my work rebuilding the carb, I decided to tear it apart again, check it thoroughly, clean it thoroughly, reinstall it and then tested it again… and then did it again… and then did it one more time only to get the same thing happening. She’d start up, run for just a bit and then quit with a big sneeze. Being that Holley’s come with so many changeable parts for tuning, I thought maybe the new power valve I installed was the wrong size and so I tore things apart again so that I could reinstall the old one and it was in fact a different size but… it changed nothing.

Completely at wits end, I started thinking about just buying a new carburetor. As much as I would have loved to just install an old MC2100, that would require me to buy and install a new 2-barrel intake manifold and that was a slippery slope that I didn’t want to go down. The easiest bet was for me to just get another square bore 4-barrel carb like an Edelbrock or a 470 Holley Truck Avenger which was something I had been eyeing for a while now anyway. And, just as I was removing Jane’s existing carb for the last time, I just happened to notice something that I hadn’t noticed before – on the back of the plastic manifold/carburetor spacer, I saw for the very first time what looked like a big chip in it or more specifically, a point where something had broken off. Under closer scrutiny, I realized that what I was seeing was the remains of a large manifold vacuum port – most likely where the PCV hose was connected to and was now a MASSIVE VACUUM LEAK!

In the end, that was my problem all along – a stupid vacuum leak. It’s hard to believe that something so easy to fix could take so much time to find and I’m still kicking myself for it. While I was able to get her running again, I decided to still replace her existing Holley 4160 with a Truck Avenger being that it has a cfm closer to what an AMC 304 would want and because it’s specifically made for off-roading. With it installed, Jane fired right up and after dialing in her timing, she now runs better than ever before.

Recent Comments